On a multi-floor hotel renovation or large-scale commercial build, time isn’t just money—it’s revenue. Every day a room is out of service, the project’s ROI diminishes. While many factors contribute to delays, one of the most underestimated is the installation of finishing hardware like drapery tracks. Traditional, piecemeal installation methods create logistical friction, waste, and costly bottlenecks.

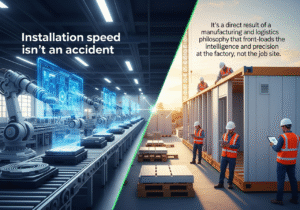

Installation speed isn’t an accident; it’s a direct result of a manufacturing and logistics philosophy that front-loads the intelligence and precision at the factory, not the job site.

Here are 10 proven strategies that professional curtain track systems employ to dramatically reduce installation time and ensure your project stays on schedule and on budget.

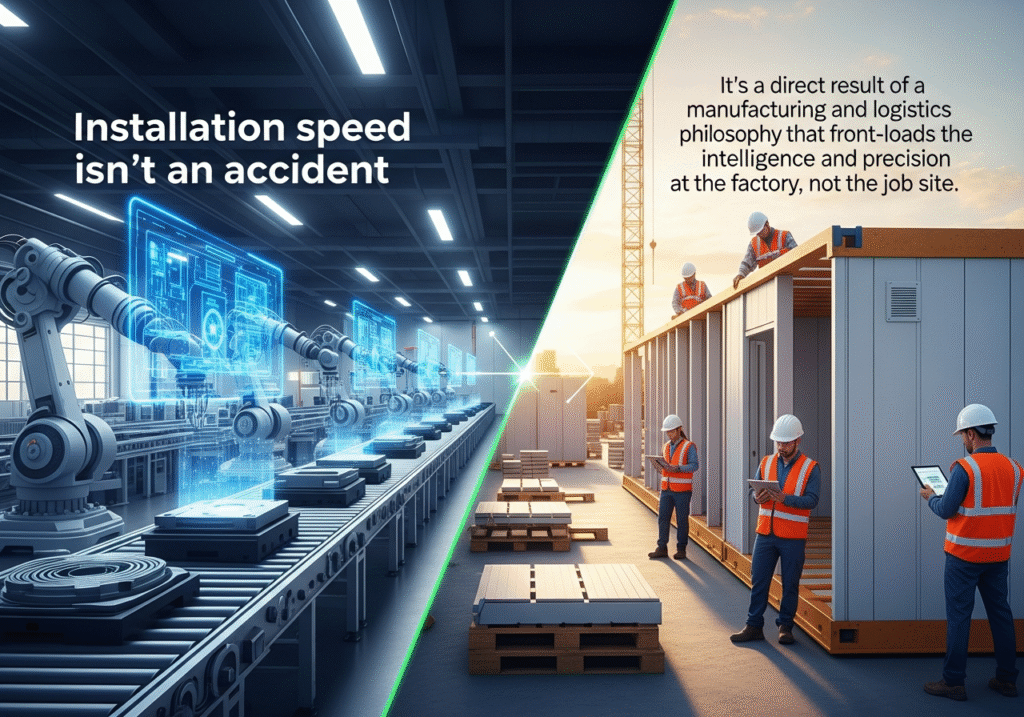

1. The End of the On-Site Workshop: Factory Pre-Cutting & Kitting

The old way: Installers spend hours on-site measuring window bays, cutting raw track stock (creating noise and aluminum dust), and sorting through boxes of brackets, screws, and end caps.

The professional system: Every track is precision-cut to the exact specifications from the architectural drawings at the factory. Each unit is then kitted with a pre-counted, complete set of components—brackets, carriers, screws, and hardware—and sealed. The installer arrives with a "kit of parts" for each room, eliminating cutting, measuring, and sorting entirely.

The Impact: Reduces on-site labor costs by up to 30% per room and eliminates material waste and measurement errors.

2. From Chaos to Clarity: Strategic Labeling & Distribution

The old way: A single delivery of hardware creates a chaotic staging area where crews waste valuable time searching for the right track lengths and components for a specific room or floor.

The professional system: Shipments are organized with a clear logistical hierarchy. Pallets are labeled by floor, and individual track kits are marked by room number (e.g., "Floor 3, Room 301 – Window A"). This allows for swift and accurate distribution from the loading dock directly to the point of installation.

The Impact: Minimizes logistical bottlenecks and prevents costly errors from installing the wrong hardware in the wrong location.

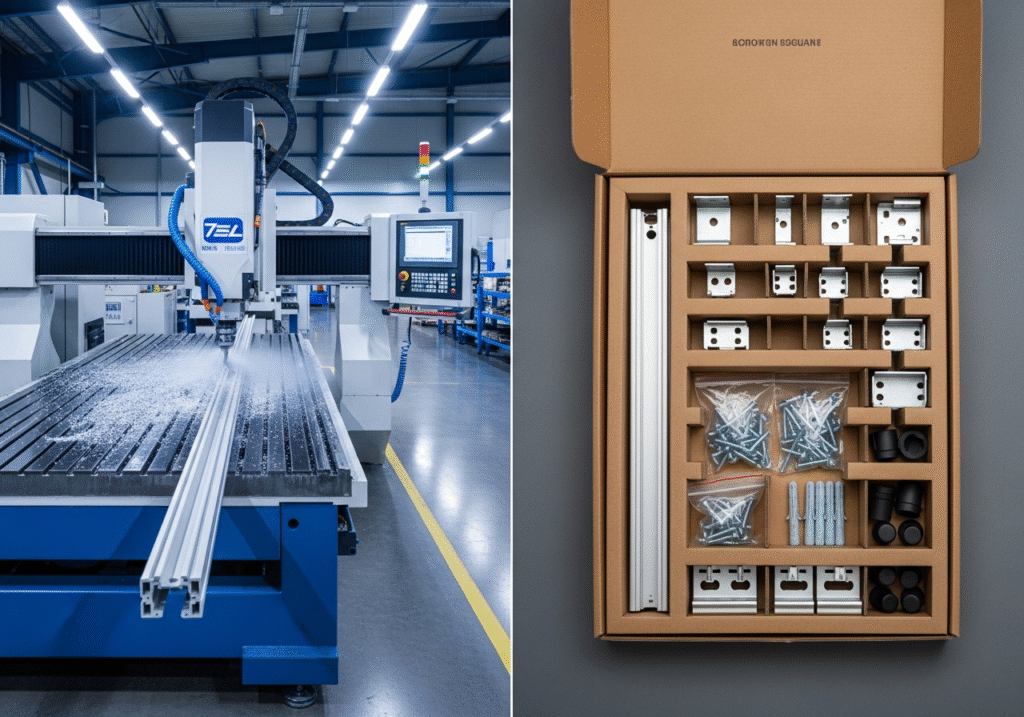

3. Plug-and-Play Simplicity: Factory-Assembled Smart Systems

The old way: Installing motorized tracks requires specialized on-site labor to mount motors, thread belts, install carriers, and perform complex wiring and programming for each unit—a process that can take hours.

The professional system: Motorized track modules arrive as pre-assembled, plug-and-play units. The motor is already mounted, the belt is tensioned, carriers are installed, and basic programming is completed at the factory. Installation is reduced to mounting the track and connecting it to a power source.

The Impact: Cuts installation time for complex motorized systems from hours to minutes and ensures higher reliability and consistency.

4. Precision and Pace: The Right Tools for the Job

The old way: Using basic hand tools can lead to misaligned brackets, uneven track runs, and time-consuming rework to correct errors.

The professional system: Experienced installation teams use specialized equipment. Laser levels ensure perfect horizontal alignment across long spans, jigs and templates guarantee consistent bracket placement, and precision power tools ensure secure mounting.

The Impact: Increases both the speed and the quality of the installation, resulting in a flawless final appearance and eliminating costly callbacks.

5. Proactive Problem-Solving: The Value of Experience

The old way: An unexpected piece of in-wall blocking, a concrete header, or a slightly non-plumb wall can halt an inexperienced installer for hours while they search for a solution.

The professional system: Experienced installation teams use specialized equipment. Laser levels ensure perfect horizontal alignment across long spans, jigs and templates guarantee consistent bracket placement, and precision power tools ensure secure mounting.

The Impact: Prevents minor on-site issues from cascading into major project delays.

6. The Power of Teamwork: Coordinated Large-Scale Installation

The old way: A single installer struggling with a 20-foot track in a ballroom or a heavy, curved system in a lobby creates a significant bottleneck and safety risk.

The professional system: For large or heavy components, teams are coordinated to work in unison. One group can manage logistics and preparation while another focuses on lifting and mounting, turning a day-long task for one person into an hour-long process for a team.

The Impact: Dramatically accelerates the installation of statement pieces and oversized systems common in hospitality and commercial spaces.

7. Measure Twice, Install Once: Pre-Installation Verification

The old way: Arriving on-site to discover that final wall dimensions don’t match the original blueprints, forcing costly emergency orders and schedule changes.

The professional system: A dedicated pre-installation site check is a mandatory step. Installers or project managers verify critical dimensions, check for surface flatness, and confirm structural support before the product is even shipped. This acts as a final layer of quality control.

The Impact: Guarantees that the factory-kitted materials are 100% correct, ensuring a smooth, uninterrupted installation process.

8. On-Demand Customization: Flexible and Bendable Track Designs

The old way: A curved wall or bay window not on the original plans would require new measurements to be sent back to the factory, leading to weeks of delay.

The professional system: Utilizing high-quality, on-site bendable track profiles1 allows installers to create perfect curves and custom shapes to fit as-built conditions in real-time. This provides critical adaptability, especially in renovation projects with architectural irregularities2.

The Impact: Offers the speed of a standard installation with the flexibility of a fully custom solution, eliminating lead times for unique layouts.

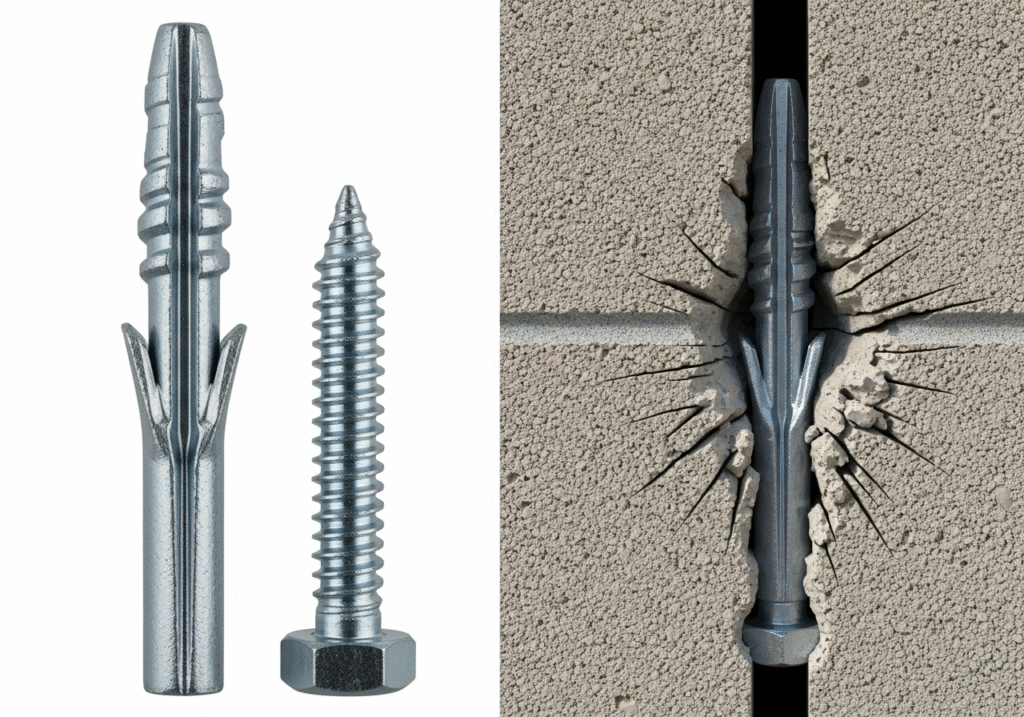

9. Engineered for Success: Load-Rated Hardware & System Compatibility

The old way: Using generic screws or anchors that aren’t suited for the wall material (e.g., drywall vs. concrete) can lead to sagging tracks, failures, and time-consuming repairs.

The professional system: Professional track systems are designed with specified load ratings3. The hardware kits include tested anchors and screws4 specifically matched to the project’s defined wall types, ensuring a secure and permanent installation from the start.

The Impact: Prevents installation failures and post-completion repairs, safeguarding the project’s reputation and budget.

10. The Foundation of Speed: Early Planning & Walk-Throughs

The old way: The drapery track installer is brought in at the last minute, only to discover a conflict with an HVAC vent, a sprinkler head, or a light fixture.

The professional system: Installation planning begins during the design phase. A review of shop drawings and pre-installation site walk-throughs5 with the GC and other trades allows the team to identify and resolve these conflicts on paper, long before they become expensive on-site problems.

The Impact: Ensures the final installation phase is a smooth, conflict-free process that proceeds without interruption.

Conclusion

Ultimately, rapid installation is not just about the hardware itself—it’s about the entire ecosystem built around it. By choosing a professional curtain track partner, you are investing in a process designed to de-risk your project, respect your timeline, and deliver a higher-quality result. It’s a partnership in efficiency that pays dividends in reduced labor costs, predictable schedules, and rooms ready for revenue sooner.

Frequently Asked Questions (FAQ)

1. What is the typical lead time for factory pre-cut and kitted orders?

Lead times vary by project scale, but the key benefit is that manufacturing happens in parallel with your site preparation. By providing architectural plans early, the tracks are ready for delivery precisely when the site is ready for installation, eliminating the on-site fabrication delays common in traditional methods.

2. How do your motorized systems integrate with existing hotel automation or Building Management Systems (BMS)?

Our motorized systems are designed for universal compatibility. They use standard communication protocols (like Dry Contact, RF, or Zigbee) to integrate seamlessly with major guest room automation systems (Crestron, Lutron, Control4, etc.), creating a true "plug-and-play" experience for your tech team.

3. What happens if final on-site measurements differ slightly from the architectural plans?

This is precisely why our process includes a pre-installation verification step. If discrepancies are found during that final check, we can make adjustments before production. For minor, unexpected variations found during install, our experienced teams and flexible track options are equipped to make on-the-fly adaptations.

4. Can our own general contractor’s team install these systems?

While our systems are designed for simplicity, we recommend using our certified installation teams for large-scale projects. Their specialized tools, experience with our products, and troubleshooting expertise are what guarantee the maximum speed and quality outlined in the article.

5. How does the labeling system work on a complex site with multiple room types?

The labeling is highly specific. A typical label includes the floor, room number, and a unique identifier for the window if there are multiple types (e.g., "Floor 12, Room 1214 – King Suite, Bay Window"). This removes all guesswork for the distribution crew.

6. What are the most common "hidden obstacles" your expert teams encounter and solve?

Common issues include unexpected concrete or steel headers above windows, conflicts with recently installed HVAC or sprinkler lines, and non-plumb walls in older renovation projects. Our teams can solve these instantly with specialized anchors, minor bracket adjustments, or by notifying the GC of a necessary change.

7. How much on-site space is required for staging the materials?

Significantly less than with traditional methods. Because everything is kitted by room, boxes can be distributed directly to their respective floors or even individual rooms upon arrival. This eliminates the need for a large, chaotic central staging area where components would need to be sorted.

8. For curved walls, is an on-site bendable track as durable as a factory-curved one?

Yes. Our professional-grade bendable tracks are engineered from high-quality aluminum that maintains its structural integrity and smoothness after shaping. For projects with highly precise, repeating curves (e.g., every room in a curved tower), a factory bend is efficient. For unique or irregular curves, on-site bending is faster and more flexible.

9. What specific information do you need for the "Early Planning" phase?

Ideally, we need the architectural drawings (DWG or PDF files), window schedules, and specifications for wall construction (e.g., drywall with metal studs, concrete block). This allows us to plan track lengths, bracket placement, and the correct load-rated hardware from the very beginning.

10. What is the actual time savings per room compared to a traditional installation?

While it varies by project complexity, clients regularly report time savings of 30-50% per room. The elimination of on-site cutting, measuring, parts-sorting, and troubleshooting translates directly into fewer labor hours and faster room turnover.

Relate

-

Explore this link to understand how bendable track profiles enhance flexibility and adaptability in construction projects. ↩

-

This resource will provide insights on effectively managing architectural irregularities during renovations. ↩

-

Understanding load ratings is crucial for ensuring safety and effectiveness in installations. ↩

-

Exploring this topic will highlight the significance of using reliable hardware for secure installations. ↩

-

Exploring the benefits of pre-installation site walk-throughs can enhance your project’s efficiency and conflict resolution. ↩