Introduction:

Briefly explain that in commercial projects, curtain tracks are not decorative accessories but critical infrastructure. Highlight the risks of specifying under-engineered products (e.g., failure, maintenance costs, safety hazards) and introduce the 7 key engineering features as a blueprint for success.

1. High Load-Bearing Capacity

- Engineering Rationale: Crucial for supporting heavy, specialized fabrics like blackout, acoustic, or insulated drapery common in hotels and theaters. Prevents sagging and deformation over long spans.

- Performance Benchmarks: Specify a minimum continuous load capacity of 10-20 kg per meter. Mention the ability to support dynamic loads of over 100 kg for heavy-duty applications.

- Material & Design Specifications: Detail a profile wall thickness of at least 1.5-2.0mm. Describe the importance of reinforced profile geometry and heavy-duty carriers made from POM with steel axles.

- Installation & Safety Considerations: Emphasize the need for correct bracket spacing (e.g., every 50-60 cm) and using load-rated anchors appropriate for the substrate (concrete, steel, drywall).

2. Durable and Corrosion-Resistant Materials

- Engineering Rationale: Ensures longevity and aesthetic integrity in high-traffic or harsh environments (e.g., humidity in hospitality bathrooms, coastal air, cleaning chemicals in hospitals).

- Performance Benchmarks: Mention resistance to a 500-hour salt spray test (ASTM B117) without visible corrosion. Reference UV stability to prevent discoloration.

- Material & Design Specifications: Specify high-grade 6063-T5 aluminum alloy. Detail surface treatments like anodizing (≥15μm thickness), electrophoresis, or powder coating for superior protection.

- Installation & Safety Considerations: Note that corrosion resistance applies to all components, including screws and brackets, to prevent a single point of failure.

3. Smooth and Silent Gliding Operation

- Engineering Rationale: Essential for user experience in quiet-sensitive environments like hospital patient rooms, luxury hotel suites, and executive boardrooms. Reduces operational strain on manual and motorized systems.

- Performance Benchmarks: Describe a pull force of less than 1 kg to move a 10 kg curtain. Mention a tested lifecycle of over 20,000 open/close cycles without degradation in performance or noise increase.

- Material & Design Specifications: Focus on precision-engineered carriers with sealed ball bearings or self-lubricating POM (Polyoxymethylene) rollers.

- Installation & Safety Considerations: A smooth glide prevents jarring motions that could loosen brackets over time and reduces user effort, increasing compliance with manual operation.

4. Flexibility for Custom Configurations

- Engineering Rationale: Modern architecture often incorporates non-linear designs. This feature allows for continuous, functional drapery across bay windows, curved walls, and around corners without unsightly gaps or joints.

- Performance Benchmarks: Specify ability to achieve a consistent minimum bend radius (e.g., 30 cm) without kinking or compromising the glide channel.

- Material & Design Specifications: Differentiate between factory pre-bent tracks for perfect uniformity and on-site bendable profiles made from tempered aluminum for custom adjustments.

- Installation & Safety Considerations: Proper bending requires specialized tools to avoid damaging the track finish or profile. Ensure curved sections have adequate bracket support to handle lateral forces.

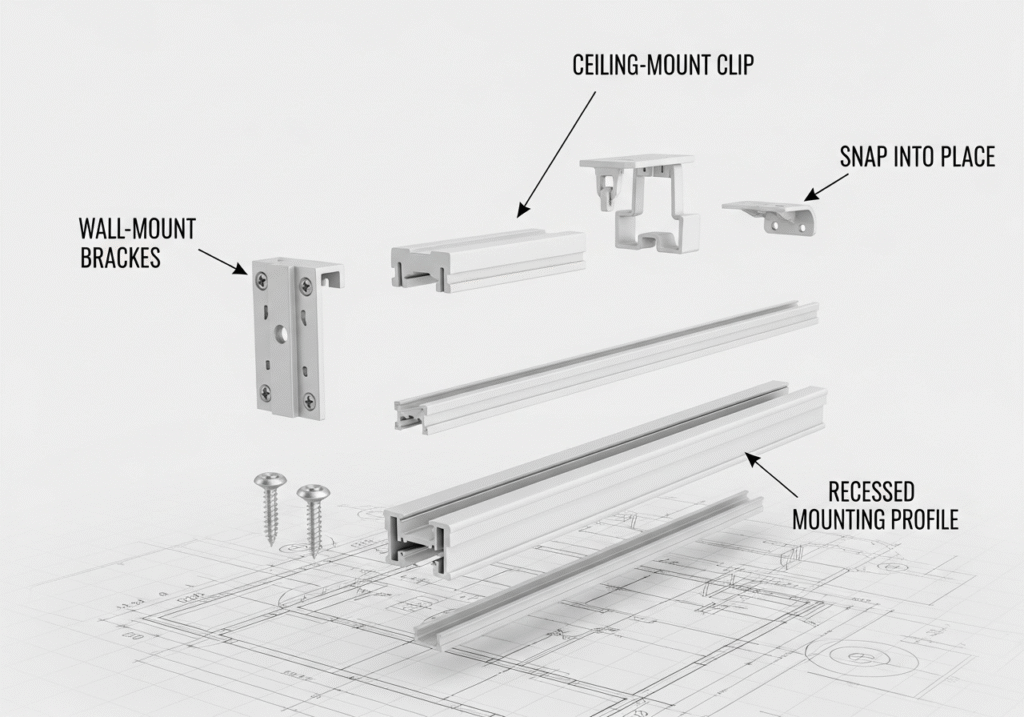

5. Versatile Mounting and Installation Options

- Engineering Rationale: Provides solutions for any architectural condition, from exposed concrete ceilings to suspended grid systems or walls with limited structural support points.

- Performance Benchmarks: System should be tested and certified for all advertised mounting methods (ceiling-mount, wall-mount, recessed/embedded).

- Material & Design Specifications: Showcase different bracket designs: adjustable wall brackets, direct-to-ceiling clips, recessed profile housings, and suspension kits with steel cables.

- Installation & Safety Considerations: Recessed installations require early coordination with architects and builders. Versatile systems reduce on-site improvisation, leading to safer and faster installs.

6. Enhanced Safety and Reliability Features

- Engineering Rationale: In public and commercial spaces, system failure is a liability. Redundant safety features are non-negotiable to protect property and people.

- Performance Benchmarks: Brackets should have a failure point at least 3x the track’s rated load. Specify features like carrier brakes that engage when encountering an obstruction.

- Material & Design Specifications: Describe components like overload clutches in motorized systems, secure locking mechanisms on brackets, and master carriers designed not to detach from the track.

- Installation & Safety Considerations: All safety features must be installed according to manufacturer specifications to be effective. This includes using specified end-stops and overlap arms.

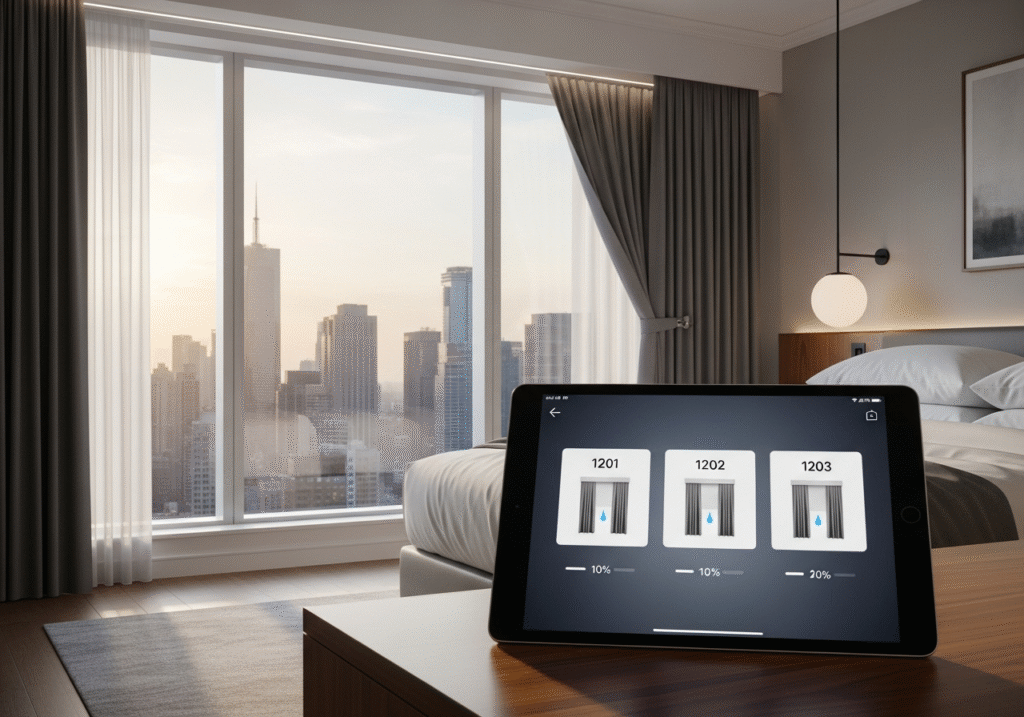

7. Efficient and Automated Control Mechanisms

- Engineering Rationale: Provides operational efficiency, accessibility (ADA compliance), and sophisticated control for large or hard-to-reach windows. Enables integration into smart building systems.

- Performance Benchmarks: For motorized systems, specify quiet operation (<40 dB). For manual cord-drawn systems, mention gear reduction mechanisms that ease operation for very heavy curtains.

- Material & Design Specifications: Detail options for RF/Wi-Fi motorized systems with BMS integration capabilities (Dry Contact, RS485). Mention durable, tangle-resistant cords and pulley systems for manual options.

- Installation & Safety Considerations: Motorized systems1 require certified electricians2. Planning for power supply and control wiring must be done early in the project timeline.

Guideline

Provide actionable advice for importers.

- Certification & Compliance: Stress the importance of verifying ISO 9001 (Quality Management), CE (European Conformity), and RoHS (Restriction of Hazardous Substances) certifications. Explain what each one means for product quality and safety.

- Sourcing Considerations: Discuss the advantages of sourcing from established manufacturing hubs like China, highlighting access to advanced production technology, economies of scale, and experienced export partners. Advise on how to identify top-tier suppliers versus trading companies.

Conclusion

Summarize by stating that specifying commercial curtain tracks based on these seven engineering features is an investment in durability, safety, and long-term operational excellence. Reinforce that partnering with a qualified, certified supplier is as important as the product specifications themselves.

Frequently Asked Questions (FAQ)

1. What is the key difference between a heavy-duty residential track and a true commercial-grade track?

The primary difference lies in certified performance and material science. Commercial tracks are engineered and tested for thousands of cycles under heavy loads (10-20 kg/m or more), use thicker-walled aluminum (1.5mm+), and have certified corrosion resistance (e.g., 500-hour salt spray test), ensuring they withstand the high-use and demanding environments of public spaces.

2. How do I determine the required load-bearing capacity for a project?

First, calculate the total weight of your specified drapery (fabric weight per square meter x total area). Then, add a safety margin of at least 20-30% to account for dynamic stress from daily operation and potential user misuse. Always provide this total weight to your supplier to ensure they specify an appropriate track profile.

3. When should I specify an aluminum track versus a steel track?

Specify high-grade aluminum (like 6063-T5) for the vast majority of applications, including hotels and hospitals, due to its excellent strength-to-weight ratio and superior corrosion resistance with finishes like anodizing. Reserve steel tracks for extreme, specialized industrial applications requiring exceptionally high load capacities where aesthetics and corrosion are less of a concern.

4. How do motorized curtain tracks integrate with a Building Management System (BMS)?

Quality motorized systems are designed for integration. They typically offer multiple control interfaces, such as Dry Contact (simple open/close relays), RS485, or RF/Zigbee gateways, allowing them to be seamlessly controlled by major automation systems like Crestron, Lutron, or a central BMS for synchronized, building-wide operation.

5. What is considered a "silent" track in terms of a decibel (dB) rating?

For environments like luxury hotels or hospitals, a high-performance motorized track should operate at a noise level below 40 dB. This is equivalent to a quiet library and is achieved through precision-engineered motors and carriers with sealed ball bearings.

6. What is the performance difference between a factory-bent and an on-site bendable track?

Factory-bent tracks offer perfect, consistent radii, ideal for projects with many identical curved windows. On-site bendable tracks offer maximum flexibility for custom shapes, renovations, or irregular curves discovered during installation. Both maintain full structural integrity and smooth gliding when executed with the correct tools and expertise.

7. Why is ISO 9001 certification important when selecting a supplier?

ISO 9001 certification is not about the product itself, but about the manufacturer’s quality management system. It proves the supplier has reliable, repeatable processes for design, production, and inspection, which dramatically reduces the risk of defects, inconsistencies, and shipping errors in your order.

8. Can our general contracting crew install these commercial track systems?

While possible for skilled crews, it is highly recommended to use a manufacturer’s certified installation team for large-scale projects. They possess specialized tools (e.g., for bending and recessed installs), are faster, and their expertise ensures the system’s performance and warranty are fully upheld.

9. How does an "overload clutch" work on a motorized track?

An overload clutch is a critical safety feature. If the curtain snags on an object (like furniture or a window latch) during operation, the clutch detects the spike in motor resistance and automatically disengages the drive. This prevents the motor from burning out and protects the fabric and track from damage.

10. What maintenance is required to ensure the longevity of commercial curtain tracks?

High-quality commercial tracks are designed for minimal maintenance. Recommended practice includes a semi-annual visual inspection of brackets and carriers, and cleaning the track channel with a dry cloth to remove any accumulated dust that could impede the smooth gliding of the rollers.