Choosing between aluminum and steel tracks feels confusing. A wrong decision can lead to sagging curtains and unhappy clients. Let’s break down the key differences for a perfect choice.

Aluminum tracks are lightweight, corrosion-resistant, and ideal for most residential and commercial uses, especially for curved applications. Steel tracks offer superior strength and are best for extremely heavy, wide-span curtains, but they are heavier and can rust if not properly treated.

I’ve spent years working with both materials, right from the factory floor. I’ve seen which tracks hold up and which ones fail under various conditions. The choice isn’t just about the metal itself. It’s about matching the material to the project’s specific needs, your budget, and long-term goals. Over the years, I’ve helped partners like Matt, an experienced Purchasing Manager in the US, navigate these choices. Let’s dig into the details so you can make the best decision for your customers and your business.

How do aluminum and steel compare in material strength and durability?

Worried your curtain tracks won’t support heavy drapes? A bending or failing track can ruin a project and your brand’s reputation. Let’s compare their strength to ensure lasting performance.

Steel is inherently stronger and more rigid than aluminum, making it the top choice for exceptionally heavy or wide curtains. However, high-quality extruded aluminum offers excellent strength for most applications, from residential sheers to commercial blackout drapes, with better flexibility.

When I think about strength, I go back to my early days in the factory, handling both materials daily. Steel has a clear advantage in raw power. Its higher tensile strength means it can handle massive loads without bending. This makes it a must-have for specialty projects like stage curtains or extra-wide hotel lobby drapes. However, this rigidity is also a limitation because it makes steel difficult to bend or customize on-site.

Aluminum, on the other hand, provides a fantastic balance. Here’s how I break it down for our partners:

Load-Bearing Capacity

I always tell my customers that modern aluminum alloys are surprisingly strong. For over 90% of window treatment projects, a well-engineered aluminum track is more than sufficient. We design our profiles to maximize strength while keeping the product lightweight.

Durability and Environmental Factors

Aluminum naturally forms a protective oxide layer1, making it highly resistant to rust and corrosion. This is a huge advantage for projects in humid climates or coastal areas. Steel, unless it is stainless or has a robust powder coating or galvanized finish, is vulnerable to rust2 over time. A small scratch in the finish can expose the metal and start the corrosion process, which can stain curtains and weaken the track.

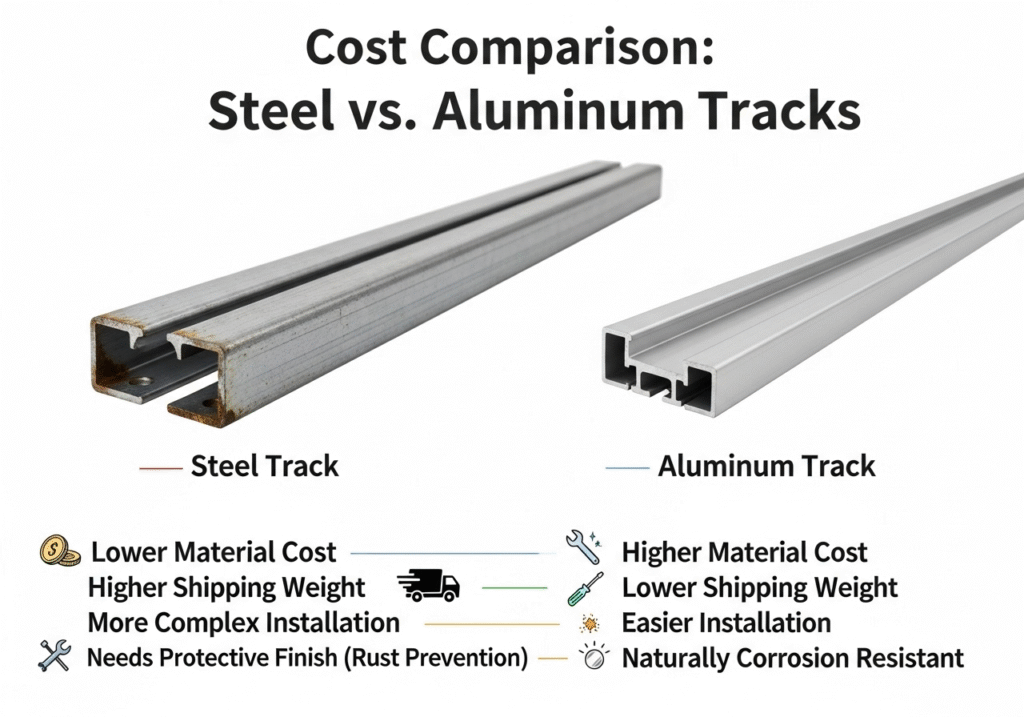

What are the cost considerations when budgeting for aluminum vs. steel curtain tracks?

You need to balance your budget without sacrificing quality. Choosing the wrong material based on price alone can lead to higher long-term costs from replacements and maintenance issues.

Generally, steel curtain tracks have a lower initial material cost than aluminum. However, the total project cost can be higher due to increased shipping weight, more complex installation, and the need for protective finishes to prevent rust, which can narrow the price gap.

I’ve managed a lot of production runs, and the cost discussion is always central. It’s easy to look at the raw material price per kilogram and assume steel is cheaper. And often, it is. But as a purchasing manager, you know the total cost of ownership goes far beyond the initial price tag. The real picture emerges when you factor in everything from shipping to installation.

Here’s a table I often use to help partners like Matt evaluate the true cost:

| Cost Factor | Aluminum Tracks | Steel Tracks |

|---|---|---|

| Material Price | Higher initial cost | Lower initial cost |

| Shipping | Lower cost due to light weight3 | Higher cost due to heavy weight4 |

| Finishing | Minimal; naturally corrosion-resistant | Higher cost for powder coating/galvanizing |

| Installation | Faster and easier; often a one-person job | Slower and more difficult; may need two people |

| Customization | Easier and cheaper to bend for bay windows | Difficult and expensive to bend |

When you add it all up, the financial advantage of steel can shrink, especially for complex or large-volume orders. Aluminum’s lower shipping and installation costs often offset its higher material price, making it a more economical choice overall for many standard projects. My advice is to always request a quote that includes shipping and any necessary finishes to see the full picture.

Which material works best for different application scenarios?

Using the right material for the wrong setting leads to failure. A track for a lightweight sheer curtain in a home is very different from one for a heavy blackout drape.

Aluminum is highly versatile and the best choice for residential settings, curved windows, and most commercial projects due to its lightweight nature and corrosion resistance. Steel is the specialist, excelling in industrial applications or where extreme weight and width are factors.

From my experience on the factory floor and working with clients, matching the track to the environment is the key to success. You wouldn’t use a delicate tool for a heavy-duty job. The same logic applies here. Aluminum’s flexibility makes it my go-to recommendation for a wide range of situations. It can be easily bent into smooth curves for bay windows, a task that is very difficult and costly with steel. Its clean look and variety of finishes also fit well with modern interior designs.

For steel, its strength defines its purpose. Think about places where failure is not an option and the load is immense.

Let’s look at specific scenarios:

Common Project Applications

- Residential Homes: I almost always recommend aluminum. It’s strong enough for drapes, easy for homeowners or contractors to install, and won’t rust in bathrooms or kitchens.

- Hotels and Hospitality: Aluminum is the workhorse here. We supply miles of aluminum tracks for hotel rooms because they are reliable, quiet, and handle daily use. For grand ballrooms with floor-to-ceiling drapes, steel might be considered.

- Hospitals and Clinics: Aluminum is preferred. It can be specified with antimicrobial finishes, and its smooth operation is ideal for privacy cubicle curtains.

- Theaters and Stages: This is steel’s domain. The sheer weight and size of stage curtains demand the unmatched strength that only steel can provide.

What’s the difference in maintenance and lifespan between the two?

You buy hardware that is built to last. A track that needs constant cleaning or fails prematurely reflects poorly on your company and erodes profit margins with warranty claims.

Aluminum tracks offer a longer, virtually maintenance-free lifespan due to their natural resistance to rust and corrosion. Steel tracks, while durable, require a pristine finish to prevent rust and may need periodic checks, especially in humid or coastal environments.

Long-term performance is where the true value of a product is revealed. My goal has always been to manufacture products that our partners can sell with confidence, knowing they will last for years. When it comes to curtain tracks, the primary enemy of longevity is corrosion. This is where aluminum truly shines. Since aluminum doesn’t rust, the track will maintain its structural integrity and smooth appearance for decades with little more than an occasional dusting. The gliders will continue to run smoothly without being impeded by rust buildup inside the channel.

Steel, on the other hand, lives and dies by its protective coating. At Yuson, we use high-quality powder coating to seal our steel tracks. This creates a tough, durable barrier. However, any deep scratch or chip that exposes the raw steel to moisture creates a failure point. Once rust begins, it can spread under the coating, causing it to flake and compromising the entire track. This is why I caution partners about using steel in high-moisture areas like bathrooms or near the sea, as the risk of corrosion is much higher.

Conclusion

Ultimately, aluminum is the versatile, low-maintenance choice for most projects, while steel is the heavy-duty specialist. Understanding these differences helps you select the best value for your specific application.

Related:

-

Understanding the protective oxide layer can help you appreciate aluminum’s durability and its applications in various environments. ↩

-

Exploring why steel is vulnerable to rust will enhance your knowledge of material properties and their implications in construction. ↩

-

Exploring this link will provide insights into how lightweight shipping can save money and improve efficiency. ↩

-

Understanding this concept can help you make informed decisions about shipping logistics and pricing. ↩