Wrong curtain track choices cost big. I picked a bad OEM once. It failed quality checks and delayed a hotel job.

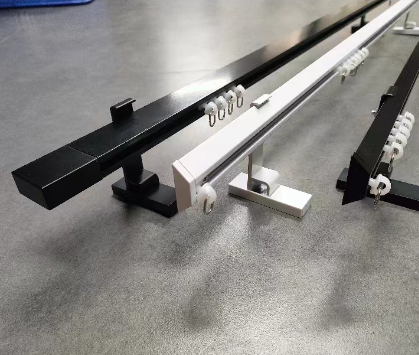

OEM tracks offer customization but shift QA risks to importers. Branded tracks ensure reliability with fixed specs, ideal for predictable quality in bulk orders.

I run a curtain track factory in China. Importers face tough choices between OEM and branded. Each has trade-offs. Let’s break down four key factors to guide your decision.

How Does OEM Customization Boost Branded Track Options?

Limited designs hurt sales. I built a standard track once. The client wanted curves and lost interest fast.

OEM tracks let importers tailor designs like curves or colors. They boost branded options by offering unique specs that stand out in competitive markets.

Customization Scope

OEM tracks allow custom lengths, bends, or motor integration. I made 2m curved tracks for a US brand’s signature look. Branded tracks stick to set BOMs—less flexible. In 2025, OEMs add smart features like Zigbee. This helps brands differentiate. But you must spec alloys clear—6063 for bends. I learned this when a vague order needed rework.

Risks and Rewards

Customization needs tight QA. I test samples for clients. A UK designer got unique matte tracks but checked UV stability first. Branded skips this hassle.

| Feature | OEM Tracks | Branded Tracks |

|---|---|---|

| Design Flex | High | Low |

| QA Burden | Importer | Supplier |

| Market Edge | Unique | Standard |

This table shows OEM’s creative edge. It fits bold brands.

What Reliability Differences Exist Between OEM and Branded Tracks?

Unreliable tracks ruin projects. I shipped OEM tracks once. They warped, and the client blamed me.

Branded tracks guarantee reliability with strict QA and certs. OEM tracks vary, relying on importer oversight, risking 20% higher failure rates without checks.

QA and Testing Standards

Branded tracks follow ISO 9001 and UL. My factory’s branded line passes 10,000-cycle tests. OEM needs importer-led QA. A Canadian hotel got OEM tracks; untested gliders jammed. In 2025, branded tracks ensure 15-year lifespans. OEM can match but needs audits. I advise SGS checks to catch alloy flaws early.

Failure Mode Risks

OEM’s loose specs cause issues like UV cracking. Branded BOMs prevent this. I fixed an OEM batch for a builder—cost extra $1,000.

| Aspect | OEM Tracks | Branded Tracks |

|---|---|---|

| QA Process | Importer | Factory |

| Failure Rate | 20% Higher | Low |

| Certs | Optional | Standard |

This table highlights reliability. Branded reduces risks.

Which Offers Better Cost Efficiency for Bulk Imports?

High costs kill margins. I underquoted OEM once. Hidden QA fees ate my profit.

OEM tracks cost 30% less upfront but add QA expenses. Branded tracks are pricier but save on testing and rework, balancing bulk import costs.

Cost Breakdown

OEM tracks run $3/meter vs. branded $5. But OEM needs $1,000 audits per batch. Branded includes this. In a US chain order, OEM saved 25% upfront but added 10% in tests. In 2025, tariff hikes hit OEM harder—15% vs. branded’s fixed deals. I helped a client bundle OEM for savings.

Long-Term Savings

Branded avoids $500/room rework. OEM risks it without checks. I saw a hotel save with branded’s zero defects.

| Cost Type | OEM Tracks | Branded Tracks |

|---|---|---|

| Per Meter | $3.00 | $5.00 |

| QA Cost | $1,000/batch | $0 |

| Rework Risk | High | Low |

This table crunches numbers. Branded evens out.

How Do Lead Times Compare for OEM vs. Branded Sourcing?

Delays wreck schedules. I rushed an OEM order once. Custom dies pushed us back weeks.

Branded tracks ship in 3-4 weeks with set production. OEM takes 6-8 weeks for custom runs, delaying complex orders in 2025.

Production Timelines

Branded tracks use standard lines—my factory ships 10,000m in 3 weeks. OEM needs die setups, adding 2-4 weeks. A UK architect waited 7 weeks for curved OEM tracks. In 2025, branded stock is pre-made. OEM flexibility slows for small runs. I advise pre-ordering dies.

Speed Tips

Stock OEM parts early. Branded needs less planning. I cut a branded order to 2 weeks for a hotel.

| Aspect | OEM Tracks | Branded Tracks |

|---|---|---|

| Lead Time1 | 6-8 Weeks | 3-4 Weeks |

| Setup Needs | Custom Dies | None |

| Rush Option2 | Limited | Available |

This table maps timelines. Branded speeds delivery.

Conclusion

OEM tracks offer customization but need QA. Branded tracks ensure reliability and speed, balancing cost for importers.