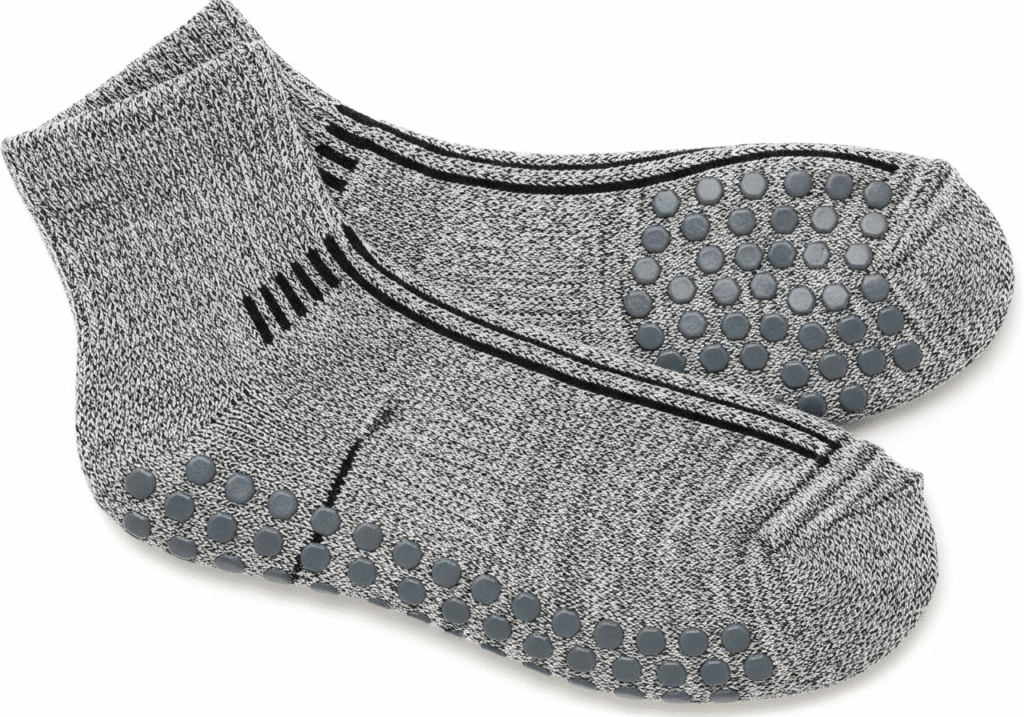

Are you sourcing grip socks that quickly lose their shape, comfort, or grip? This leads to unhappy customers and damages your brand's reputation for quality.

High-quality grip socks are not made from a single "best" material. They are crafted from a smart blend of fibers, combining a comfortable base like cotton with durable synthetics like nylon and stretchable spandex, plus a high-performance grip application.

As a purchasing manager, Matt knows that the final product is only as good as the raw materials it's made from. My years in the sock industry taught me that the secret to a great grip sock isn't just the grip itself, but the foundation it's built on. Let's walk through the key material decisions that separate a premium sock from a mediocre one.

What Material Are Grip Socks Made Of?

It can be confusing to look at a sock's label and see a list of different fibers. Choosing the wrong combination can result in a product that either wears out too fast or feels uncomfortable.

Grip socks are made from a strategic blend of materials. This typically includes a primary fiber like cotton for comfort, a reinforcing fiber like nylon for durability, and an elastic fiber like spandex for a snug fit.

When I first started in a sock factory, I was amazed at how different yarn combinations could completely change the feel and performance of the final sock. It's truly a science. The blend isn't random; each component is chosen for a specific purpose to create a balanced, high-performing product.

The Role of Each Fiber

The final fabric is a team effort where each fiber plays a critical role. Understanding these roles is key to sourcing a quality product.

| Fiber Category | Common Materials | Primary Function |

|---|---|---|

| Comfort Base | Cotton, Combed Cotton, Merino Wool | Provides softness, breathability, and moisture absorption. |

| Durability | Nylon, Polyester | Adds strength, abrasion resistance, and helps the sock last longer. |

| Stretch & Fit | Spandex (Lycra, Elastane) | Delivers elasticity for a snug fit and shape retention. |

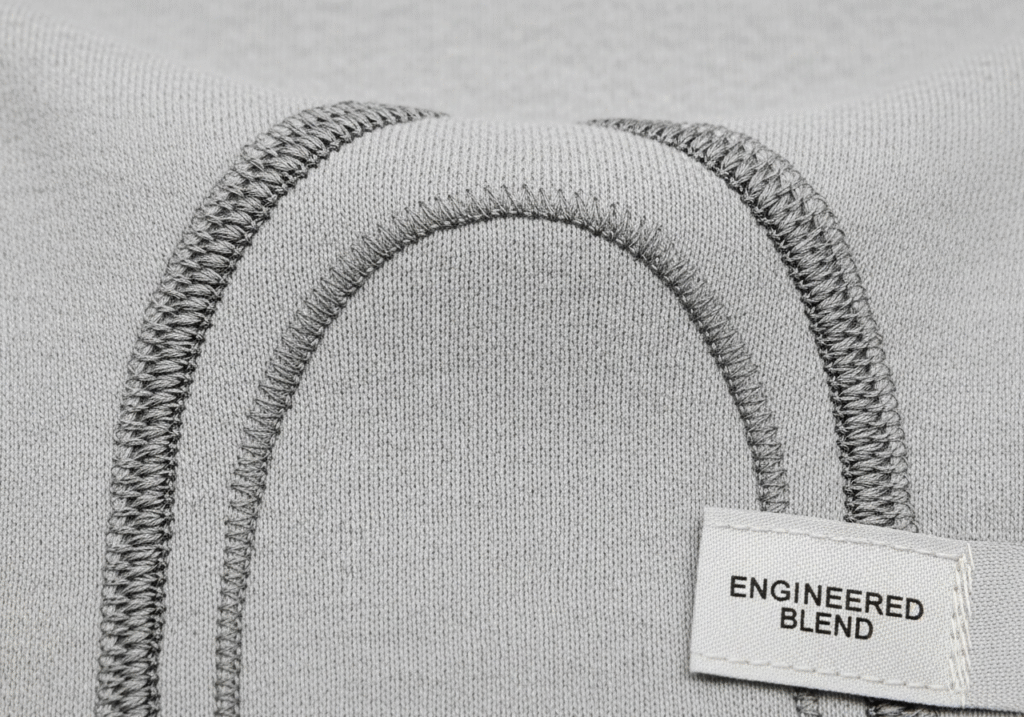

The exact percentages of this blend are often a manufacturer's secret recipe, perfected over years of testing. This "recipe" is what defines the sock's final character and performance level.

What Is the Best Fabric for Grip Socks?

You might think that a sock made from 100% of a premium material would be the best. But picking just one often means sacrificing another key attribute, like durability for comfort, or vice versa.

There is no single "best" fabric. The best result comes from a skillfully engineered blend. A combination of soft combed cotton, durable nylon in high-wear zones, and spandex for arch support creates a superior performance fabric.

The goal is to create a synergy where the final fabric is better than the sum of its parts. A 100% cotton sock might feel soft, but it will stretch out and wear through quickly. A 100% nylon sock would be incredibly durable but feel rough and sweaty. The magic is in the mix.

Engineering the Ideal Blend

A professional sock isn't just thrown together; it's engineered for its specific use.

- Use Combed Cotton: I always recommend combed cotton over standard cotton. The combing process removes short, breakable fibers, leaving only the longest and strongest ones. This results in a sock that is both incredibly soft and much more durable.

- Reinforce Key Areas: The heel and toe areas see the most friction. A good manufacturer will knit these sections with a higher percentage of nylon to prevent holes and extend the life of the sock.

- Integrate Arch Support: By weaving spandex into the arch area, you can create a compression band. This provides support, reduces foot fatigue, and ensures the sock stays firmly in place during activity, which is critical for a grip sock.

- Integrate Arch Support: By weaving spandex into the arch area, you can create a compression band. This provides support, reduces foot fatigue, and ensures the sock stays firmly in place during activity, which is critical for a grip sock.

This kind of thoughtful construction is a clear sign of a high-quality supplier.

What Material to Avoid in Socks?

Sourcing based on the lowest price can be tempting, but it often leads to using inferior materials. These materials can ruin the customer experience and lead to negative reviews and returns.

Avoid socks made from 100% acrylic or standard, uncombed cotton. Acrylic is not breathable and can feel scratchy, while cheap cotton absorbs moisture without wicking it away, stretches out easily, and wears down quickly.

I've seen firsthand how cutting corners on materials can backfire. A sock that feels good for the first five minutes but leaves your feet sweaty and loses its shape after one wash is a failure. For a brand's reputation, quality and consistency are paramount.

Why Some Materials Don't Make the Cut

Here’s a closer look at why certain materials are a poor choice for performance socks.

- Acrylic: While it can be soft and inexpensive, acrylic is essentially a plastic fiber. It has very poor moisture management, trapping sweat against the skin. This can lead to blisters and discomfort, which is the last thing an athlete wants.

- Low-Grade Cotton: Standard cotton, unlike its combed counterpart, is full of short fibers. It pills easily, wears thin in high-friction areas, and once it gets wet from sweat, it stays wet. This creates a heavy, uncomfortable feeling.

- Excessive Polyester: While polyester is excellent for durability and wicking, a blend with too much of it can sometimes feel less soft or "natural" than a cotton-rich blend. It's about finding the right balance.

For a purchasing manager like Matt, specifying a blend that avoids these low-grade options is a crucial first step toward a premium product.

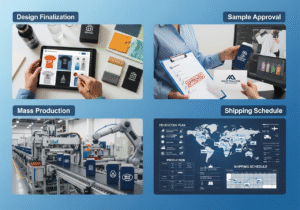

How to Make Professional Grip Socks?

A great fabric is the foundation, but it's only half the story. The manufacturing process, especially the grip application and quality control, is what turns that fabric into a professional-grade product.

Professional grip socks require advanced knitting machines for a seamless toe, a high-quality PVC or silicone grip pattern for reliable traction, and rigorous quality control checks at every stage to ensure consistency in fit, durability, and performance.

This is where a supplier's expertise truly shines. In my own company, this is the stage where we separate ourselves from the competition. Anyone can buy yarn, but not everyone can execute the manufacturing process to a world-class standard.

From Knitting to Quality Control

The key stages for creating a professional grip sock include:

- Precision Knitting: Using computerized knitting machines1 to create a sock with a seamless toe closure2. This eliminates the bulky, irritating seam found in cheaper socks. The machine can also create targeted zones for cushioning and ventilation.

- Grip Application: The anti-slip material3, usually eco-friendly PVC4 or silicone, is applied. The pattern must be designed for maximum traction without feeling bulky underfoot. The curing process is also critical to ensure the grips are durable and won't peel off.

- Strict Quality Control (QC): This is non-negotiable. Checks should happen after knitting, after grip application, and before packing. We check for size consistency, knitting defects, and grip adhesion on every batch. This ensures every pair meets the buyer's exact specifications.

A reliable partner will be transparent about their entire process, from yarn selection to final QC checks.

Conclusion

Sourcing high-quality grip socks is about balancing comfort, durability, and performance through a smart material blend and a precise, quality-controlled manufacturing process. This focus on detail delivers a superior product.

Related:

-

Explore how computerized knitting machines enhance sock quality and comfort, revolutionizing the knitting industry. ↩

-

Learn about the advantages of seamless toe closures for comfort and performance in socks. ↩

-

Explore this link to understand how anti-slip materials enhance safety and performance in various applications. ↩

-

Discover the benefits of eco-friendly PVC, including sustainability and safety, which are crucial for modern manufacturing practices. ↩