Need to order custom grip socks for your gym but worried about quality and delays? Cheap socks can damage your brand and disappoint your members.

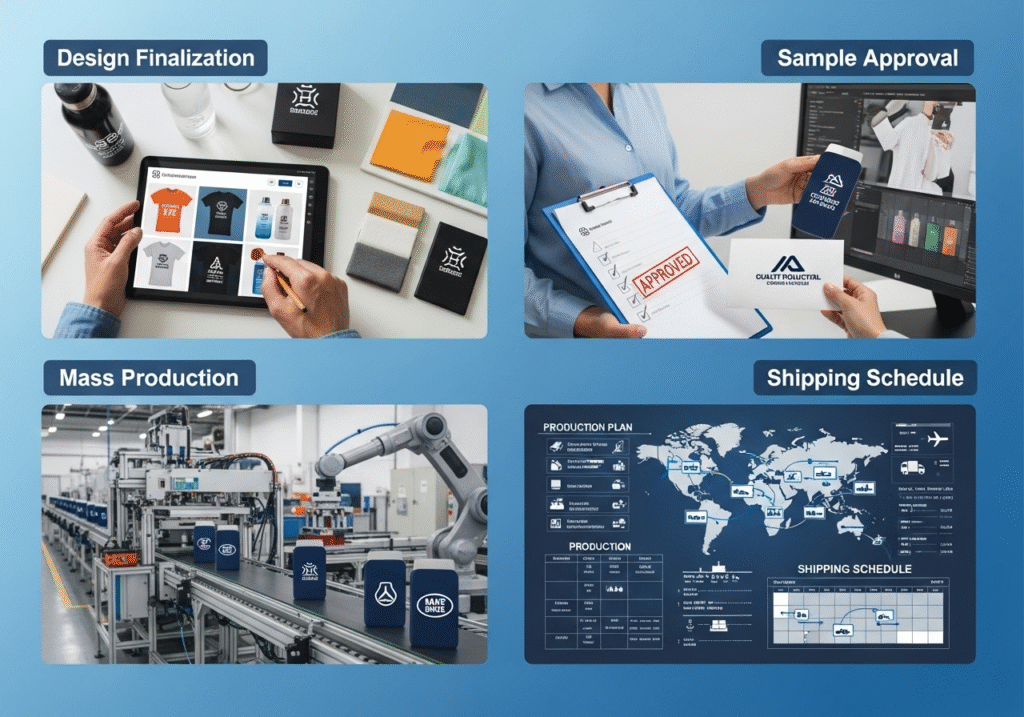

Bulk ordering requires partnering with a manufacturer who can balance professional-grade materials, custom branding, and transparent production timelines. The process involves design finalization, sample approval, mass production, and a clear shipping schedule to ensure on-time delivery without sacrificing quality.

As a purchasing manager for your gym, you're not just buying a product; you're investing in your brand. I've worked with countless gyms and studios, and I know the right supplier relationship makes all the difference. It's about finding a partner who understands that these socks represent the quality and care you provide to your members. Let's walk through the key questions you should be asking.

What Grip Socks Do Pros Use?

Want to offer the same quality grip socks that professionals use? Many retail options feel cheap and lack the durability needed for intense daily use in a gym setting.

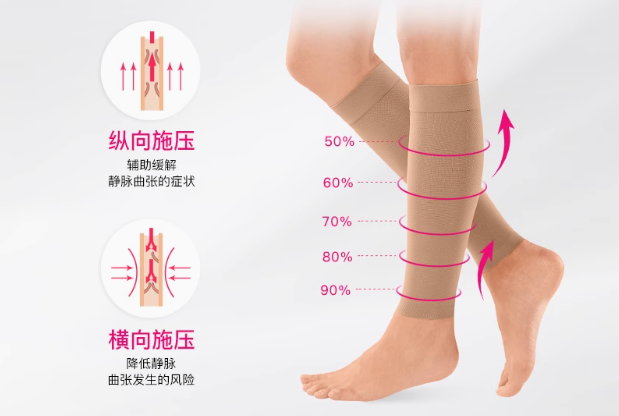

Pros use socks made from a performance blend of combed cotton for comfort, nylon for durability, and spandex for a compression fit. They feature a seamless toe, targeted cushioning, and a high-quality silicone grip for reliable traction.

When I supply socks for professional use, the standards are incredibly high. These aren't just fashion accessories; they are pieces of equipment. The construction must support intense activity and withstand constant washing. A cheap sock simply won't survive.

The Anatomy of a Professional-Grade Sock

A professional sock is engineered for performance from the yarn up.

- The Fabric Blend: The foundation is always a smart blend. We use combed cotton for superior softness and breathability, not cheap carded cotton. We then reinforce high-wear areas like the heel and toe with nylon to prevent holes. Spandex is woven throughout to provide a snug, supportive fit that doesn’t slip down during a workout.

- The Construction: A seamless toe closure is non-negotiable. It eliminates the bulky seam that can cause irritation and blisters. We also often add targeted cushioning under the ball of the foot and heel for extra comfort during high-impact activities.

- The Grip: Professionals need a grip that is consistent and durable. We use high-purity silicone, which provides excellent traction and won't peel off after a few washes, unlike cheaper PVC alternatives.

This level of detail is what separates a truly professional sock from a generic one.

How to Create Your Own Grip Socks?

You have a strong brand for your gym, but how do you translate that onto a sock? The customization process can seem confusing, with technical details about logos and colors.

Creating your own grip socks involves a simple three-step process: first, provide your logo and brand colors; second, approve a digital mockup and a physical sample; and third, confirm the final design for mass production.

This is the most exciting part for my clients. Seeing their brand come to life on a high-quality product is incredibly rewarding. My job as a supplier is to make this process as easy as possible. You bring the vision; we handle the technical execution.

From Idea to Final Product

| A good manufacturer will guide you through each stage. | Step | Your Role | Manufacturer's Role |

|---|---|---|---|

| 1. Design & Mockup | Provide your logo file (e.g., in .AI or .PNG format) and specify your brand's Pantone colors. | We create a detailed digital rendering of the sock, showing logo placement, colors, and the grip pattern for your approval. | |

| 2. Physical Sample | Evaluate the sample for feel, fit, color accuracy, and overall quality. Request any adjustments needed. | We produce a physical pre-production sample and ship it to you. This is exactly what the final product will look like. | |

| 3. Production | Give the final approval on the sample. | Once approved, we begin mass production, ensuring every single sock matches the quality of the sample you signed off on. |

This structured process removes all guesswork, ensuring the final product you receive is exactly what you envisioned for your gym.

How Long Does Production and Delivery Usually Take?

You have an event or a retail launch planned. The biggest fear is that your custom socks won't arrive on time, disrupting your plans and disappointing your members.

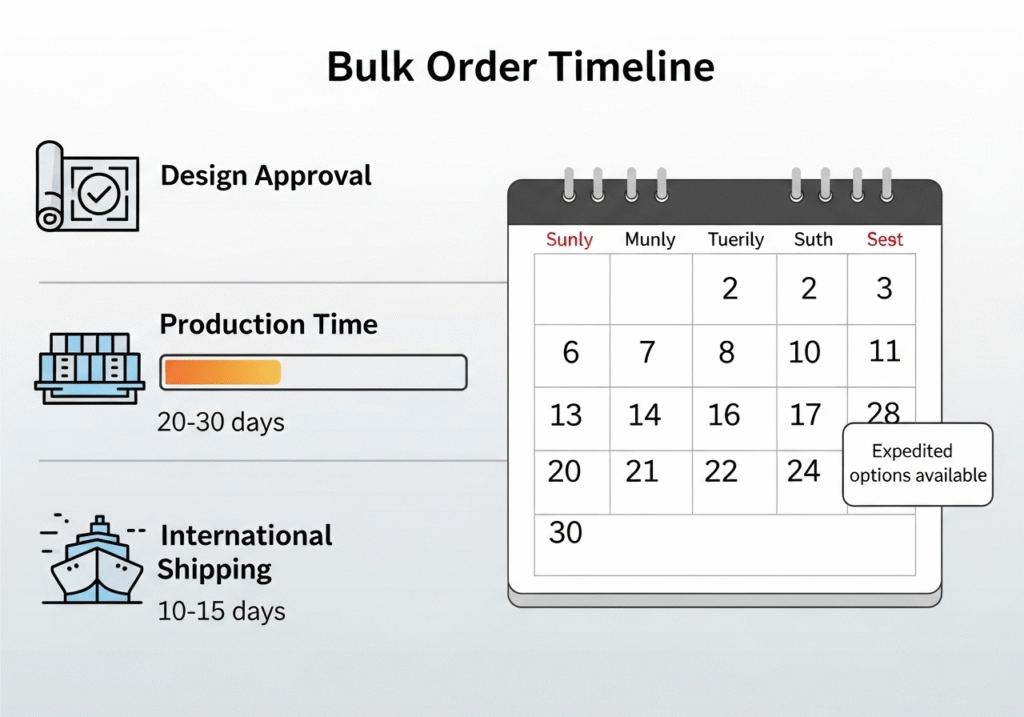

A typical bulk order, from design approval to final delivery, takes between 30 to 45 days. This includes production time (20-30 days) and international shipping (10-15 days), though expedited options are often available.

For a purchasing manager like Matt, managing timelines is everything. A reliable supplier must be transparent and realistic about their lead times. I always tell my clients that it's better to build in a small buffer than to rush the process and risk a delay.

Breaking Down the Timeline

- Pre-Production (3-7 Days): This includes finalizing the design and creating the physical sample for your approval.

- Mass Production (20-30 Days): This is the core manufacturing window. The exact time depends on the order quantity and the complexity of the design. A simple one-color logo on 1,000 pairs will be faster than a complex, multi-color design on 10,000 pairs.

- Quality Control & Packing (2-3 Days): After production, every sock is inspected before being packaged according to your specifications.

- Shipping (10-15 Days): This is the average time for sea freight, which is the most cost-effective option for bulk orders. Air freight is much faster (3-5 days) but comes at a significantly higher cost.

A professional supplier will provide a clear schedule and regular updates at each stage.

How Long Do Gripper Socks Last?

Your members will be washing and wearing these socks constantly. Will they hold up, or will the grips peel off and the fabric wear thin after just a few months?

High-quality grip socks, made with a durable yarn blend and properly cured silicone grips, are designed to last for at least 6 months to a year of regular, intensive use and washing, maintaining both their shape and grip performance.

Longevity is the true test of quality and the key to long-term value. A sock that costs 10% less but lasts half as long is a bad investment for you and your members. Durability is a core focus in my own production philosophy.

Factors That Determine Sock Lifespan

- Yarn Quality1: As mentioned, using combed cotton and reinforcing high-wear areas with nylon is critical. This prevents the sock from stretching out and developing holes prematurely.

- Grip Application2: The method used to apply and cure the silicone grips makes all the difference. We use a high-temperature curing process that permanently bonds the silicone to the fabric fibers. This ensures the grips will not peel, crack, or wash off, even in a commercial laundry setting.

- Washing Care: While our socks are built to be tough, we always recommend washing them inside out in cold water and tumble drying on low. This helps preserve the elasticity of the spandex and the integrity of the fabric for even longer.

Investing in a well-made sock means your members get a product they love, and your gym's brand remains associated with quality.

Conclusion

Bulk ordering custom grip socks is a strategic investment in your gym's brand. By focusing on professional-grade quality, a clear customization process, and a reliable supplier, you can deliver exceptional value.

Related: