High MOQs block small orders. I faced this early with a brand client. It stalled their launch.

Negotiate MOQs by starting with supplier data, offering volume commitments, and using samples. In 2025, aim for 500-1,000 units to balance costs and flexibility from Chinese factories.

I run a curtain track factory in China. We work with overseas buyers daily. MOQs set the tone for deals. Let’s break down four hot topics to guide your talks.

What Are the Typical MOQs for Bulk Curtain Tracks in 2025?

Rigid MOQs surprise buyers. I quoted 2,000 once without context. The architect walked away.

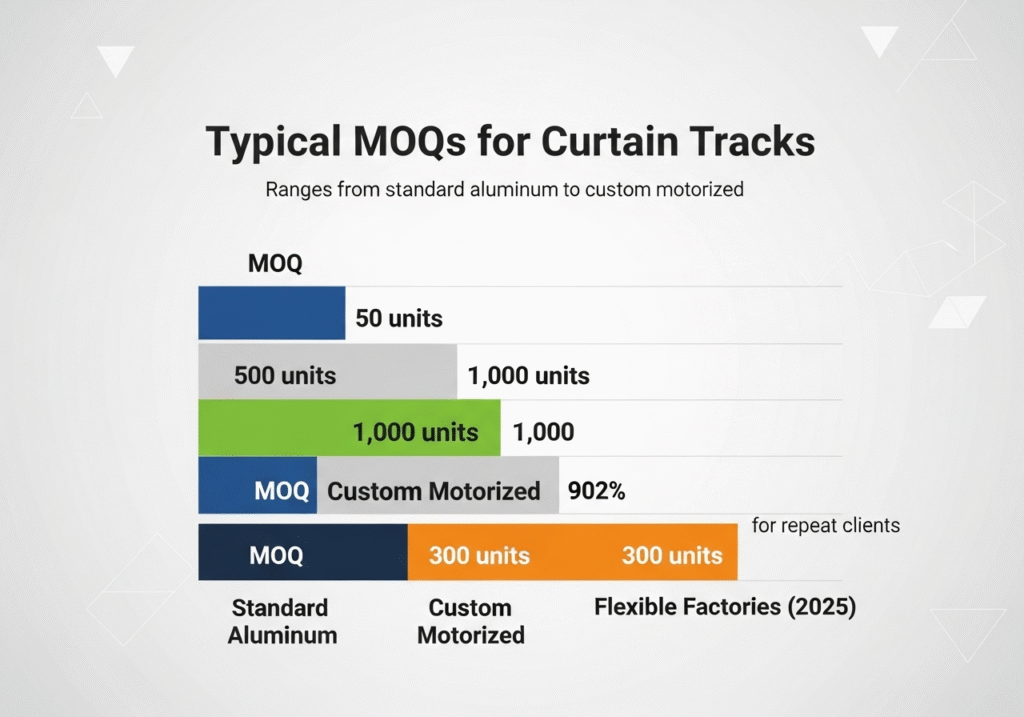

Typical MOQs for curtain tracks range from 500 units for standard aluminum to 1,000 for custom motorized. In 2025, flexible factories drop to 300 for repeat clients.

Understanding MOQ Ranges by Type

MOQs vary by product complexity. Basic tracks need less setup, so 500 suits small runs. Motorized ones hit 1,000 due to parts. From my factory, we set 800 for steel heavy-duty. In 2025, trends favor lower thresholds—Alibaba data shows 20% drop from automation. Buyers test with samples first. A U.S. intermediary started at 500 and scaled up. This builds trust without overcommit.

Factors Influencing MOQs

Material costs and production lines dictate numbers. Aluminum extrudes fast, lowering MOQs. Custom bends raise them. Check supplier capacity—full lines allow flexibility. We adjusted for a hotel chain from 1,000 to 600 on long-term promise.

| Track Type | Typical MOQ | 2025 Trend | Best For |

|---|---|---|---|

| Standard Aluminum | 500 | Down 10% | Offices |

| Motorized | 1,000 | Stable | Hotels |

| Custom Steel | 800 | Flexible | Architects |

This table spots baselines. It helps benchmark quotes.

How Can You Lower MOQs Without Losing Quality?

Pushing too hard risks subpar goods. I cut corners once. The tracks jammed on site.

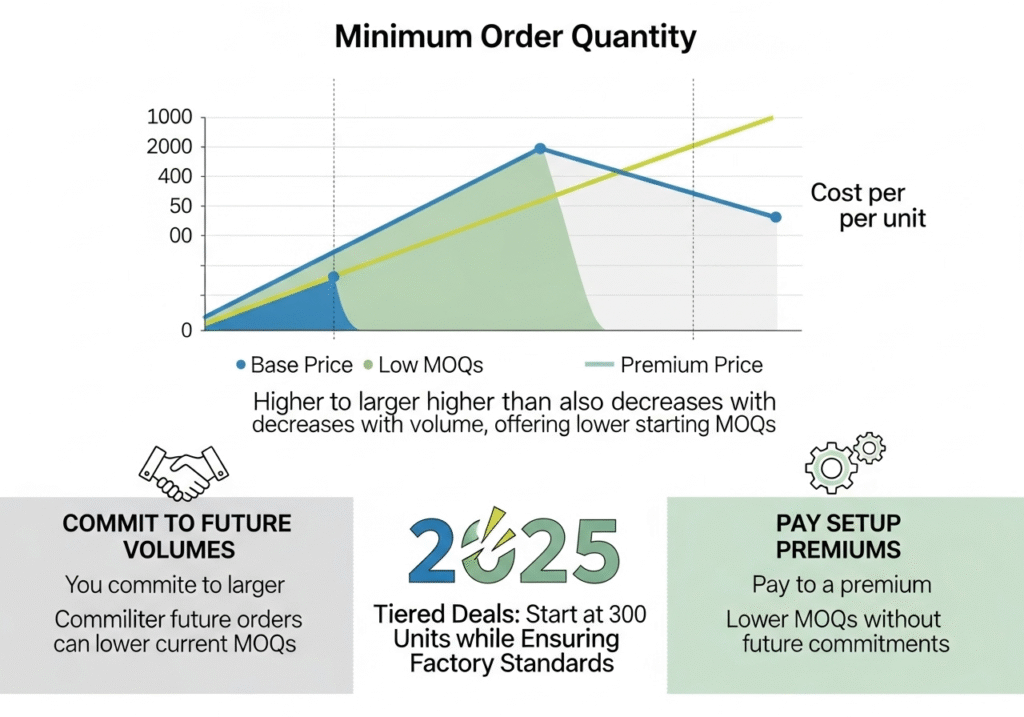

Lower MOQs by committing to future volumes or paying premiums for setups. In 2025, tiered deals let buyers start at 300 units while ensuring factory standards.

Strategies for Flexible Starts

Offer phased orders—small first, big later. We did this for a European brand: 400 initial, then 2,000. It covered tooling without waste. In 2025, shared production lines cut setup costs 15%. Use data: show your growth projections. A builder shared plans—we dropped to 350. Always verify quality via audits.

Balancing Cost and Assurance

Premiums for low runs add 10-20%. But it tests fit. Avoid verbal deals—get written terms. My client saved 25% overall by scaling smart.

| Strategy | MOQ Reduction | Quality Safeguard | Example Gain |

|---|---|---|---|

| Volume Commit | 20-30% | Contracts | 500 to 350 |

| Setup Premium | 10-15% | Samples | Test Runs |

| Shared Lines | 15% | Audits | Bulk Discounts |

This chart maps paths down. It keeps standards high.

What Role Do MOQs Play in Pricing and Lead Times?

High MOQs hide true costs. I overlooked lead impacts once. Delivery lagged two months.

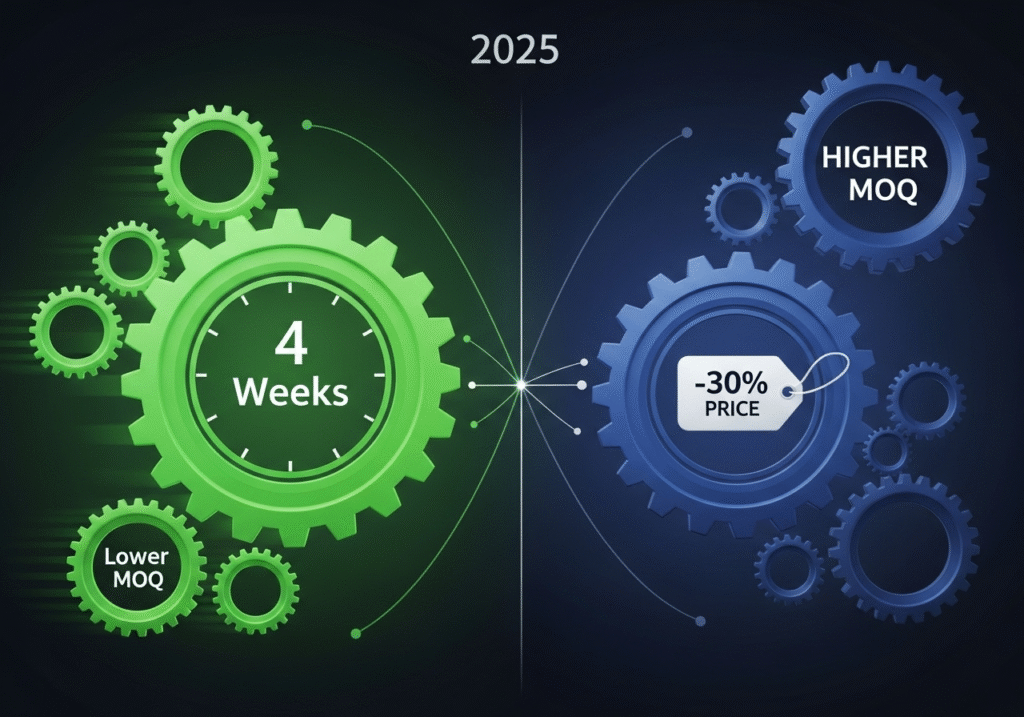

MOQs drive pricing down per unit but extend leads for customs. In 2025, lower MOQs speed production to 4 weeks, while high ones cut prices 30%.

Pricing Dynamics

Scale lowers costs—1,000 units drop to $2.50/meter from $4. Factories amortize setups. In 2025, raw metal hikes push tiered pricing. We quote 25% off at 2,000. Buyers gain by bundling accessories. A Canadian firm negotiated breaks at 600—saved 18%.

Lead Time Trade-Offs

Low MOQs queue behind big runs, adding weeks. High ones prioritize. Our lines clear customs faster for volumes. Plan buffers—2025 tariffs add scrutiny.

| MOQ Level | Price per Meter | Lead Time | Total Savings |

|---|---|---|---|

| Low (500) | $4.00 | 6 Weeks | Moderate |

| Medium (1,000) | $3.00 | 4 Weeks | High |

| High (2,000) | $2.50 | 3 Weeks | Max |

This table weighs choices. It aligns with project timelines.

How to Secure Favorable MOQ Terms in Contracts?

Weak contracts bite back. I signed loose terms once. Disputes ate profits.

Secure MOQ terms with clear escalators, penalties, and exit clauses. In 2025, include IP and quality metrics to protect buyers in volatile markets.

Key Contract Clauses

Define MOQs per phase. Add escalators for growth. We use 10% annual hikes tied to orders. Include penalties for delays—5% per week. For a U.S. architect, this ensured 800-unit starts. 2025 adds force majeure for tariffs.

Negotiation and Review

Start with templates from ICC. Get lawyers for local laws. Review samples in clauses. An intermediary locked flexible terms—avoided overstock.

| Clause Type | Purpose | Protection Level | 2025 Tip |

|---|---|---|---|

| Escalator | Growth Adjust | High | Tie to Volume |

| Penalty | Delay Control1 | Medium | 5% Weekly |

| Exit Clause2 | Flexibility | High | 30-Day Notice |

This overview strengthens deals. It builds lasting ties.

Conclusion

Negotiate MOQs with data, strategies, pricing insight, and solid contracts. Start small, scale smart for wins in 2025.