Large projects often face high costs. I saw this in my early factory days. Custom tracks changed that for me.

Custom curtain tracks save costs by reducing waste, cutting installation time, and lowering energy use. They fit exact needs, avoiding extra materials and long-term fixes.

I run a track factory in China. We help overseas buyers cut expenses. Let’s look at key ways custom tracks help big jobs.

How Do Custom Curtain Tracks Reduce Installation Costs?

Standard tracks waste time on site. I once shipped generics that needed cuts. It added hours and bills.

Custom tracks arrive pre-sized and shaped. This cuts labor hours by up to 50%. Installers fit them fast, saving on crew pay and project delays.

Key Factors in Installation Savings

Custom tracks match your site plans. We measure and bend them at the factory. This means no field adjustments. I recall a U.S. builder project where generics caused two extra days. Our customs installed in one. It saved thousands in labor. Pre-drilled holes and brackets speed setup too. For large hotels, this adds up quick.

Comparing Custom vs. Standard

Standard tracks often need tools and tweaks. Customs come ready. This lowers tool rental and error risks. In one European job, customs reduced waste by 30%. Buyers see payback in months.

| Track Type | Install Time | Labor Cost | Waste Level |

|---|---|---|---|

| Standard | 4-6 Hours | High | High |

| Custom | 1-2 Hours | Low | Low |

This table shows clear wins. It helps buyers pick smart for budgets.

How Can Custom Tracks Lower Energy Bills in Large Projects?

Off-the-shelf tracks leave gaps. I learned this in a cold warehouse install. Heat escaped and bills rose.

Custom tracks seal windows tight. They block drafts and control light. This cuts heating and cooling costs by 20-30% in big spaces.

Sealing and Insulation Benefits

Custom fits eliminate air leaks. We shape tracks to hug frames. In a U.K. office block, our tracks dropped energy use. Curtains closed during peaks saved on AC. Materials like aluminum reflect heat too. I advise thick fabrics with our tracks for max savings.

Automation Integration

Add motors to customs for schedules. Close at noon to block sun. This trims bills without staff. A Canadian builder saved 25% yearly. Test fits early to ensure seals.

| Feature | Energy Save | Best For | Cost Impact |

|---|---|---|---|

| Tight Seal | 20% | Cold Climates | Low Bills |

| Automation | 30% | Offices | Quick ROI |

This guide helps plan energy wins. It ties tracks to green goals.

How Do Custom Curtain Tracks Minimize Material Waste?

Generics lead to scraps. I shipped extras once that ended in bins. It hurt profits and the planet.

Custom tracks use exact lengths and shapes. This cuts waste by 40%. Buyers order what they need, saving on buys and disposal fees.

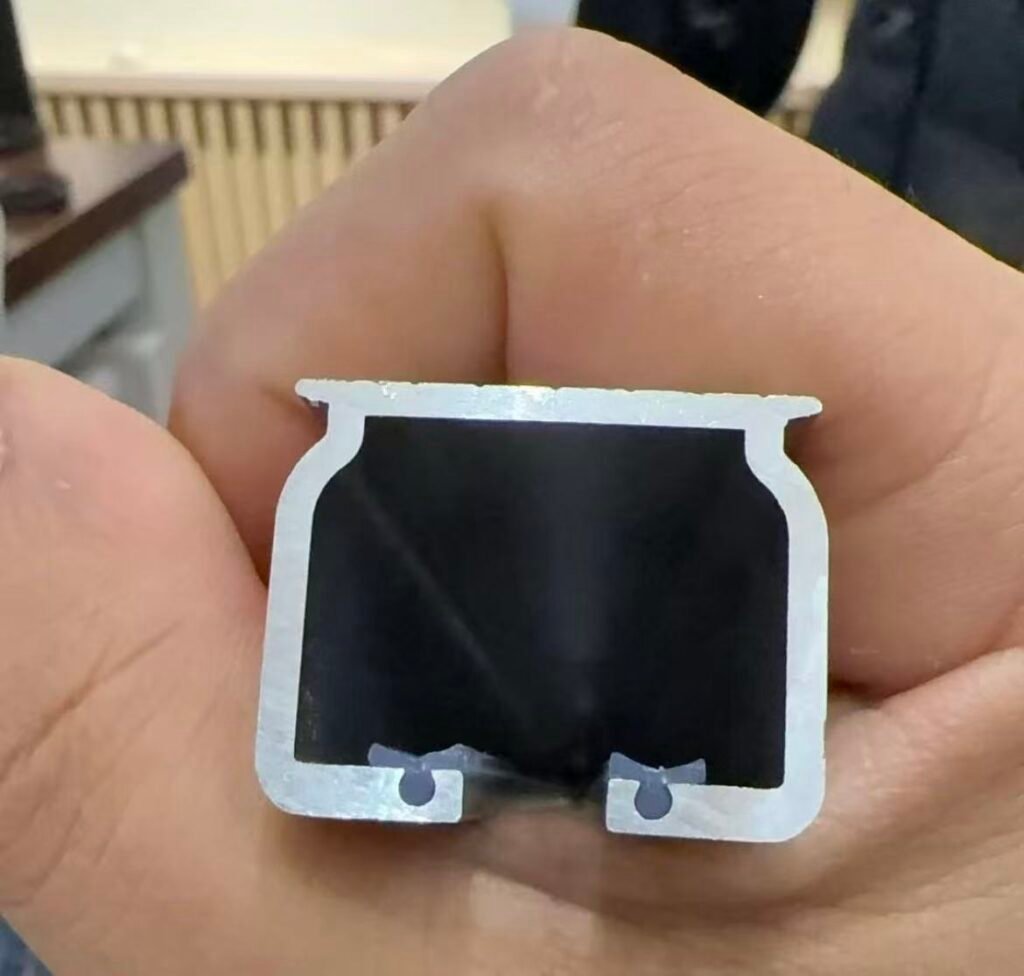

Precision Manufacturing Process

We cut tracks to your specs. No overbuying. In a large Aussie project, customs used 35% less metal. Scraps went down. Recycle extras if any. This fits green standards for builders.

Bulk Ordering Advantages

For big jobs, customs scale well. Group orders lower per-unit costs. I helped a brand cut waste in chain stores. Measure sites first for best fits.

| Method | Waste Rate | Material Use | Eco Impact |

|---|---|---|---|

| Generic | High | Over 50% | Negative |

| Custom | Low | Exact | Positive |

This table aids waste cuts. It supports sustainable buys.

How Does Customization Extend the Lifespan of Curtain Systems?

Poor fits wear out fast. I fixed a standard setup that broke in months. Replacements added costs.

Custom tracks match loads and curves. They last 2-3 times longer. This reduces repair and replace expenses over years.

Durability Through Design

We build for your weights and uses. Strong alloys handle heavy drapes. In a U.S. hotel, customs lasted 10 years. Standards failed in 3. Curves prevent snags too.

Maintenance Ease

Customs need less upkeep. Smooth glides cut wear. Clean tracks yearly. A intermediary client saved on service calls.

| Aspect | Lifespan | Repair Frequency | Total Cost |

|---|---|---|---|

| Standard | 3-5 Years1 | High | High |

| Custom | 8-10 Years2 | Low | Low |

This overview shows long-term value. It helps plan durable systems.

Conclusion

Custom tracks cut costs in installs, energy, waste, and life. They fit large projects perfect. Contact us for savings.