Are your grip sock orders facing constant delays or inconsistent quality? These production issues can hurt your brand's reputation and bottom line, leaving you with unreliable inventory.

Factories optimize grip sock production by integrating automated machinery, streamlining workflows, sourcing materials strategically, and implementing strict quality control for grip application. This creates a balanced system that delivers speed, cost-efficiency, and consistent quality for every order, large or small.

For a purchasing manager like Matt, a supplier's factory is the heart of their business. You need a partner whose production line runs like a well-oiled machine, ensuring that every shipment meets your standards and deadlines. This isn't achieved by chance. It's the result of deliberate optimization at every single step. Let's explore how a professional factory makes this happen.

How Can Factories Reduce Production Cycle Time for Grip Socks?

Are long lead times causing you to miss key selling seasons or respond slowly to market trends? Waiting months for an order can feel like a major bottleneck to your business's growth.

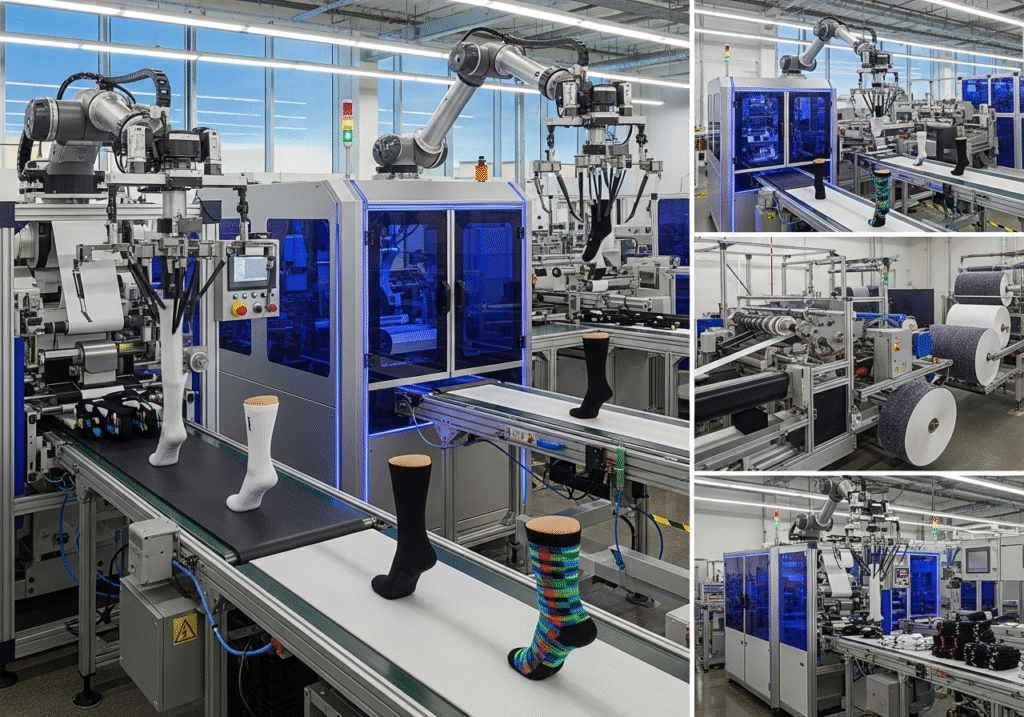

To reduce cycle time, factories use high-speed automated knitting machines and integrate subsequent steps like sock boarding and grip application into a continuous flow. This minimizes idle time between stages, moving socks from yarn to finished product much faster.

From my early days in a sock factory, I learned that the biggest time-waster wasn't the machines themselves, but the "in-between" time. Socks would be knit, then piled up in bins, waiting to be moved to the next station. Eliminating that dead time is the key to a faster production cycle.

Shifting from Stages to a Continuous Flow

The old way was a disjointed, multi-stage process. The modern, optimized approach connects these stages to create a seamless workflow.

- Advanced Automation: We use computerized knitting machines that are not only faster but also include features like automatic seamless toe linking. This completes two steps in one, immediately saving time and labor.

- Workflow Integration: Instead of storing semi-finished goods, we create a direct path. Freshly knit socks move straight to the boarding machines, where they are shaped with steam and heat. From there, they are transferred directly to the screen-printing stations for grip application.

This systematic approach can cut the total production cycle by days, or even weeks, which is a huge advantage for buyers who need to react quickly to market demands.

How Can Material Sourcing Reduce Overall Production Costs?

Are rising material costs shrinking your profit margins? It's a constant battle to find materials that meet quality standards without breaking the budget.

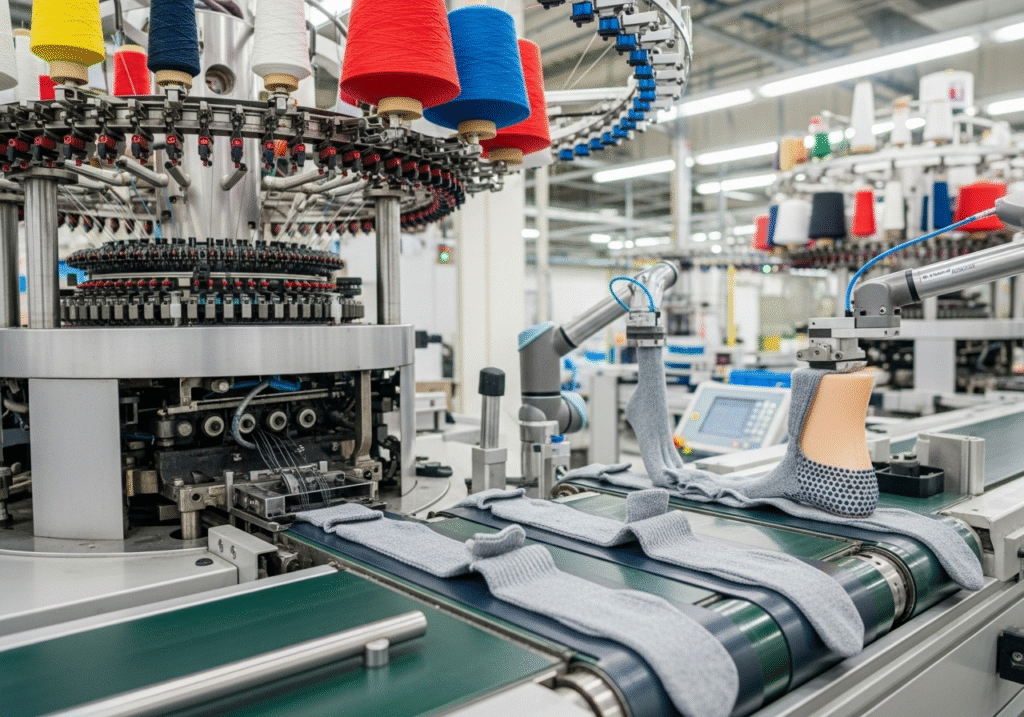

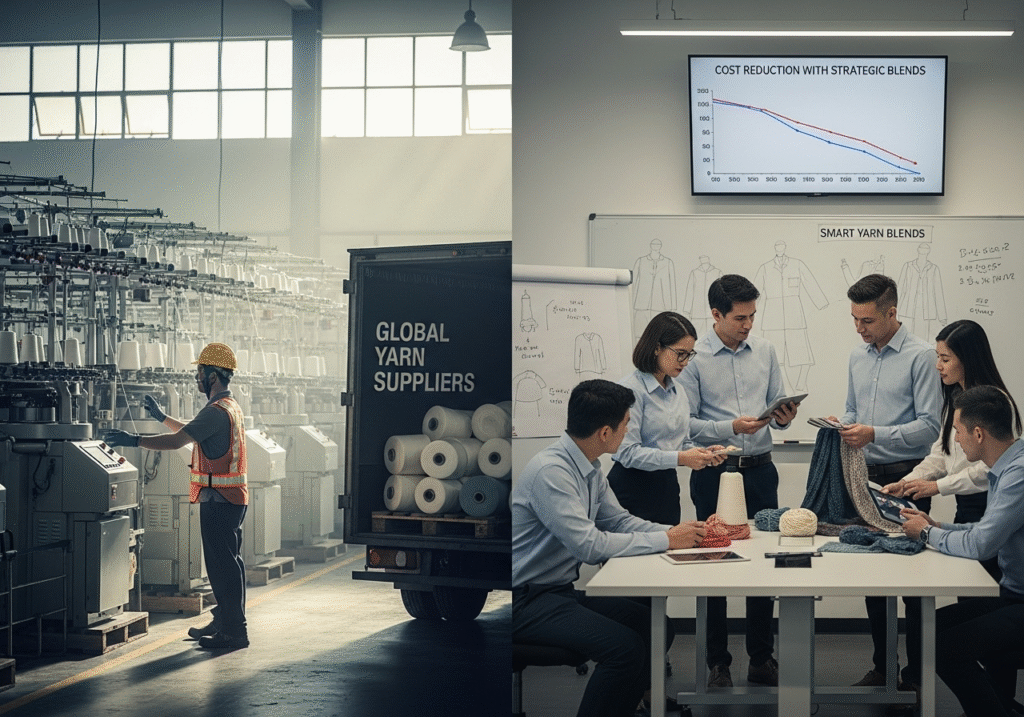

Factories reduce costs by developing long-term partnerships with yarn suppliers, which provides access to better pricing and consistent quality. Buying in bulk and engineering smart yarn blends also significantly lowers the per-unit cost without compromising performance.

My entire career has been built on understanding textiles, and I can tell you that smart sourcing is about creating value, not just chasing the lowest price. A cheaper yarn that causes production issues or fails quality checks ends up costing more in the long run.

The Value of Relationships and Smart Blends

A good factory doesn't just buy materials; it manages a material strategy.

- Strategic Supplier Partnerships: We have worked with our yarn mills for years. Because we are a loyal, high-volume customer, we get preferential pricing and access to the best materials. This stability and cost savings are passed directly to my clients.

- Optimized Yarn Blends: We can engineer a fabric to meet a specific performance and price target. For example, using premium combed cotton for softness, reinforced with a precise amount of durable nylon in the heel and toe, offers an excellent balance of comfort, longevity, and cost-effectiveness. This is far superior to using a single, cheaper material that fails on multiple fronts.

This thoughtful approach ensures our clients get the best possible product for their investment.

How Can Factories Ensure Consistent Grip Performance Across Batches?

Has your brand ever faced customer complaints that a new batch of socks isn't as "grippy" as the last one? This inconsistency can destroy customer trust and lead to costly returns.

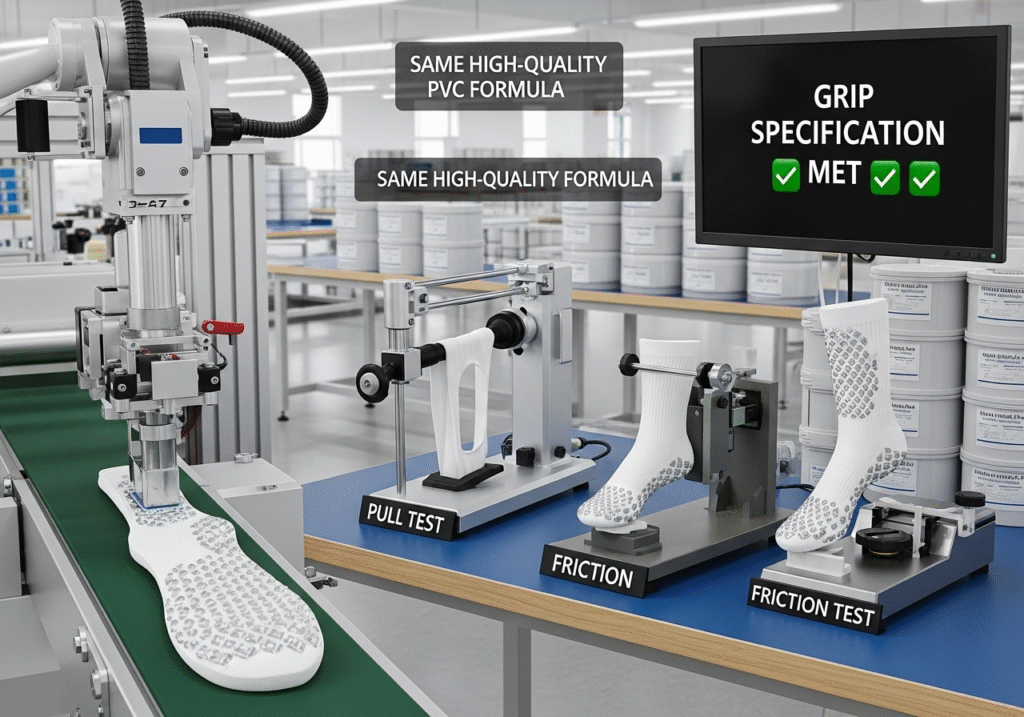

Consistency is achieved through standardized grip materials, automated application processes, and rigorous testing. Factories must use the same high-quality PVC or silicone formula for every batch and conduct systematic pull and friction tests to ensure every sock meets the grip specification.

In my experience, grip performance is not something you can leave to chance. It's a key feature that must be treated with scientific precision. A purchasing manager like Matt needs to know that the 50,000th pair of socks will have the exact same grip as the first approved sample.

A System for Reliable Grip

To guarantee this, we have a multi-step quality protocol.

- Standardized Material and Process: We use a single, pre-approved formula for our grip material and apply it using automated screen-printing machines. The curing temperature and time are precisely controlled by sensors to ensure a perfect bond every time.

- Regular Equipment Calibration: Before every major production run, our machines are calibrated to ensure the grip pattern is applied with the correct thickness and positioning.

- Batch-by-Batch Testing: We don't just inspect visually. We pull random samples from every batch and perform physical tests. This includes friction tests to measure the coefficient of grip on a standardized surface and adhesion tests to ensure the grips won't peel off after washing.

This disciplined process is the only way to deliver the reliable performance that both athletes and everyday users expect.

How Can Factories Handle Small-Batch Custom Orders Efficiently?

Does your brand want to offer limited-edition designs or personalized socks? The high setup costs and minimum order quantities (MOQs) of traditional factories can make this impossible.

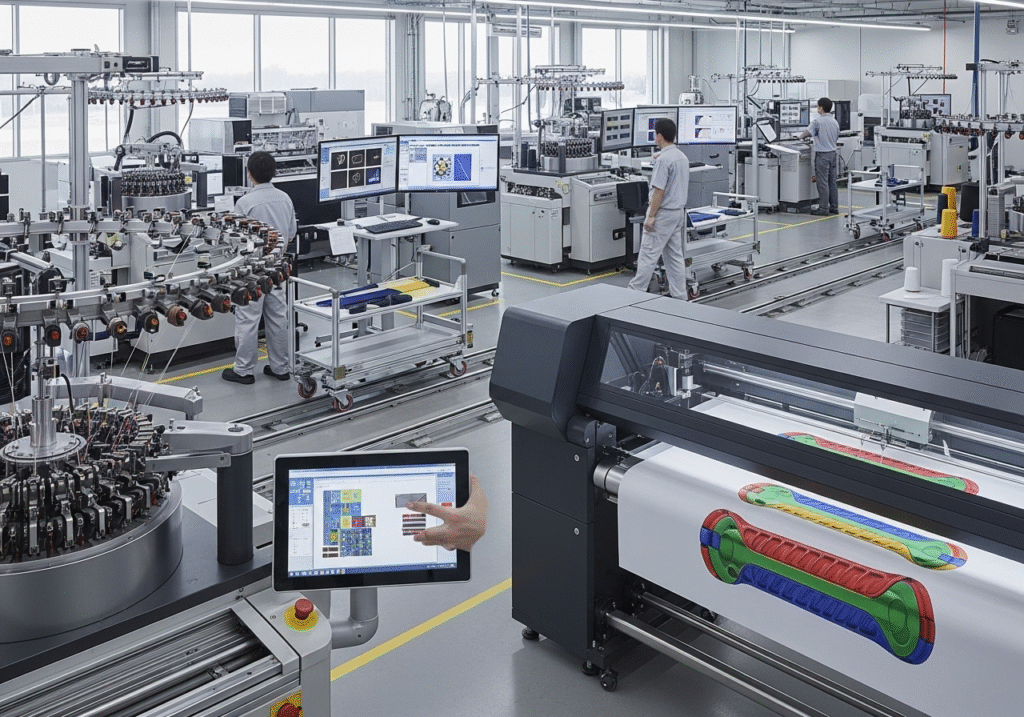

Factories handle small custom orders efficiently by leveraging digital workflows and flexible machinery. Digital pattern and grip design files can be loaded into knitting and printing machines instantly, eliminating the high setup costs and long lead times associated with physical tooling.

The ability to say "yes" to a small, custom order without adding huge costs is a massive advantage in today's market. I've built my company to be agile for this exact reason. This flexibility empowers our partners to be more creative and responsive to their customers.

The Power of a Digital-First Approach

Here’s how we make small batches economical:

- CAD/CAM Integration: Sock designs and grip patterns are created as digital files (CAD). These files are sent directly to the computerized machinery (CAM), which can switch between designs with just a few clicks. There are no physical molds or screens to create.

- Flexible Production Cells: Instead of one long, rigid production line, we can use smaller, dedicated "cells" for custom jobs. This allows us to produce a small batch for one client without interrupting a larger run for another.

- Streamlined Prototyping: This same digital process makes creating a single sample incredibly fast and cheap. A client can see their idea come to life in days, not weeks, allowing for rapid design iteration.

This technology removes the financial barriers to customization, opening up new market opportunities for our clients.

Conclusion

Optimizing a grip sock production line is a meticulous process. It requires balancing speed, cost, quality, and flexibility to build a factory that is both efficient and responsive to buyer needs.