Are your clients' architectural plans featuring more curves and corners? Standard straight hardware just won't work, forcing you to find a specialized solution that maintains both function and a high-end aesthetic.

Curved curtain tracks are essential for non-standard windows like bays and arches, and for functional applications like room dividers, privacy screens in hospitality or healthcare, and following unique architectural lines. They solve problems where straight rods or tracks are simply not an option.

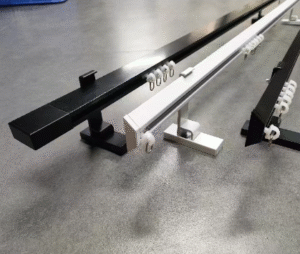

I've seen so many innovative uses for curved tracks come through our factory. While bay windows are the most common reason, architects and designers are constantly pushing the boundaries. They use our tracks to create soft, flowing walls in open-plan offices or to build elegant changing areas in high-end retail stores. The beauty of an extruded aluminum track is its incredible versatility. With the right equipment, we can shape it to follow almost any design you can imagine. This guide will walk you through the practical considerations to help you source the perfect curved track solution for your next project.

What Are Curved Curtain Tracks Actually Used For?

Are you thinking curved tracks are only for bay windows? Limiting them to that one use means you're missing out on a versatile solution that can solve many common design challenges in commercial spaces.

Curved tracks are used for bay windows, bow windows, and corner applications. Beyond windows, they serve as elegant room dividers, privacy curtains for hospital beds, shower curtains for custom stalls, and to follow the lines of curved architectural walls or features.

From my manufacturing perspective, I see the full range of applications. Hotels will order curved tracks to separate a sleeping area from a small lounge in a suite. Retailers use them for fitting rooms. We've even produced them for art galleries to create temporary, flowing exhibition walls. The core value of a curved track is its ability to move a curtain along a non-linear path. This simple capability opens up a world of design possibilities that are impossible with straight hardware.

So when you see a curved wall or an open space that needs flexible division on a floor plan, a curved track should be the first solution that comes to mind.

Can You Just Bend a Straight Curtain Track Yourself?

Is your installation team tempted to save time by bending a standard track on-site? This common shortcut often leads to a damaged product, poor performance, and an unprofessional finish that reflects badly on your company.

No, you cannot bend a standard curtain track without kinking or breaking it. You must use a track specifically designed to be "hand-bendable" or order a "machine-bent" track, which is professionally custom-curved at the factory to precise specifications for a flawless finish.

The difference is in the aluminum profile itself. A standard track is engineered for rigidity and straightness. Forcing it to bend will cause the metal to crease and break. A hand-bendable track, which we produce using a different die, often has a weaker spine or an altered internal structure that allows it to curve smoothly without collapsing. Machine-bending is a different process entirely. We take a standard, rigid track and use heavy machinery to create a perfect, permanent curve.

Here’s a quick breakdown for sourcing:

| Bending Method | When to Use It | Key Advantage |

|---|---|---|

| Hand-Bendable | Simple, on-site curves (e.g., gentle bow window). | Flexibility during installation. |

| Machine-Bent | Precise angles, high-end projects, heavy curtains. | Superior strength and a perfect curve. |

Telling your clients you use factory machine-bent tracks for their projects is a mark of quality. It shows you don't take shortcuts and are committed to a professional, durable result.

Is It Possible to Motorize a Curved Curtain Track?

Are your high-end hospitality or residential clients demanding the convenience of motorization for their curved windows? You need to know if the hardware you're sourcing can support this premium feature reliably.

Yes, it is absolutely possible to motorize a curved curtain track. Leading motor systems are engineered with powerful belts and specially designed carriers that navigate smooth, machine-bent curves effortlessly. However, the quality of the bend and the track itself is critical for quiet, reliable operation.

When we get an order for a motorized curved track, the precision of our manufacturing process becomes even more important. A motor doesn't like friction. Any imperfection or sharpness in the bend will cause the motor to strain, become noisy, and potentially fail over time. That's why we always use a high-quality, rigid track profile and a CNC bending machine for these jobs. This creates a perfectly smooth, consistent radius. The internal belt drive system runs within its own channel, and the master carriers are designed to lead the other gliders around the curve without hesitation.

For any premium project, offering a flawlessly operating motorized curved track is a huge selling point, and it starts with sourcing a perfectly engineered track.

How Do You Ensure a Smooth Glide on a Curved Track?

Are you concerned that curtains will snag or drag when pulled around a bend? A track that doesn't operate smoothly leads to frustrated end-users and costly call-backs for your team.

To ensure a smooth glide, you must use a high-quality, evenly bent track free of kinks. Utilize high-performance gliders or carriers, often with silicone-infused wheels, and ensure support brackets are placed correctly on either side of the curve to prevent sagging or twisting.

The secret to a perfect glide is minimizing friction. It's a simple physics problem we solve every day on the factory floor. First, the track's inner surface must be perfectly smooth, which is achieved through a high-quality extrusion and bending process. Second, the carriers a crucial. Standard slide-in gliders work, but for the best performance on a curve—especially with heavy curtains—wheeled carriers are superior. These small wheels roll along the track's bottom channel, dramatically reducing friction compared to a piece of plastic sliding. Finally, proper installation is key.

Brackets must support the track right before and after the curve begins1. This prevents the track from flexing under load, which would change the shape of the curve and cause the carriers to bind.

Conclusion

Ultimately, curved tracks are a powerful tool for solving complex design challenges. By choosing the right type of track and ensuring its quality, you provide a solution that is both beautiful and functional.

Relate

-

Exploring curve design can enhance your knowledge of creating efficient and effective engineering solutions. ↩