A 500-room hotel project is a massive undertaking. One small mistake in the curtain track specification can multiply into 500 problems, leading to budget overruns and damaging delays.

For a large hotel, the best solution involves a dual-track system (for sheers and blackouts), using commercial-grade aluminum tracks, and a supplier who can guarantee consistent quality and phased, room-by-room delivery to match the installation schedule.

I remember getting the initial inquiry for a 500-room business hotel in a major city center. The purchasing manager, let’s call him David, was experienced but overwhelmed by the sheer scale. His main concern wasn’t just the product; it was the logistics. He said to me, "August, I can’t have 500 sets of tracks arriving at once and sitting in a warehouse. And I can’t have 1% of them being defective. The coordination has to be perfect." He was right. A project of this size is a test of a manufacturer’s process as much as its product. This case study breaks down how we approached this challenge, from specification to final installation.

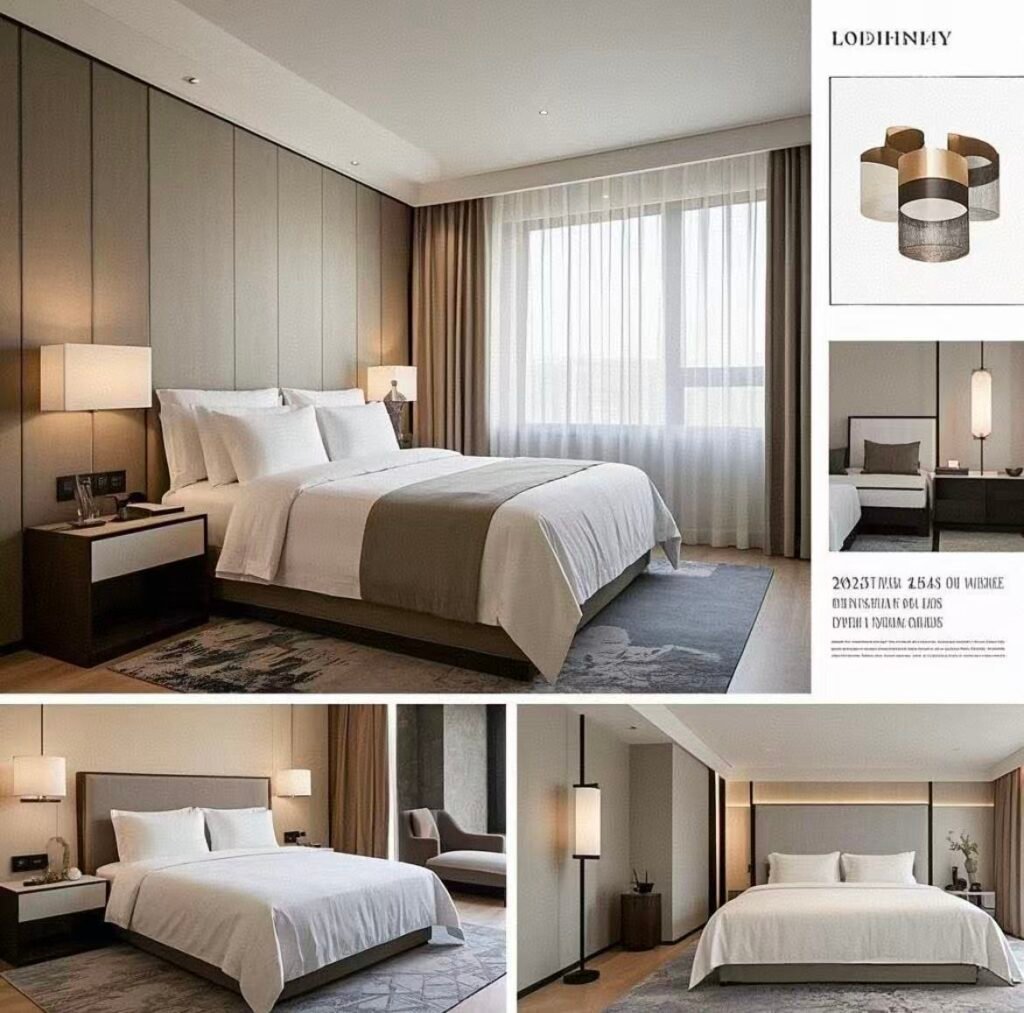

What is the point of double curtain tracks and Why do hotels almost use?

You’re planning the window treatments and notice nearly all hotels use two layers of curtains. You need to understand the functional reason behind this standard to justify the specification.

Hotels use double curtain tracks to provide guests with complete light control. One track holds a lightweight sheer curtain for privacy and diffused daylight, while the second track holds a heavy blackout curtain for total darkness.

For the 500-room project, a double track system was non-negotiable. It’s the core of a premium guest experience. David, the project’s PM, knew this well. Guests expect two things: natural light without sacrificing privacy during the day, and the ability to sleep in complete darkness at night.

The sheer curtain on the front track accomplishes the first goal, making the room feel bright and airy. The blackout curtain on the back track is crucial for sleep quality, blocking out city lights and the early morning sun. We specified two of our slim-profile, commercial-grade aluminum tracks for each window. This setup not only meets guest expectations but also adds a sense of depth and luxury to the window, elevating the entire room’s design. It’s a functional choice that has become an industry standard for a very good reason.

How do you ensure smooth curtain operation in high-use areas?

Hotel curtains are opened and closed thousands of times over their lifespan. You need a system that feels smooth and effortless for every guest, every single time, without jamming or breaking.

To ensure smooth operation, you must use a commercial-grade aluminum track with high-quality, wheeled runners (or gliders). Friction-based plastic slides will wear out and stick, but wheeled runners roll along the track, minimizing effort and noise.

This was a key performance indicator for David’s project. A stuck curtain is one of the most common guest complaints and maintenance calls. The solution lies in the small, often overlooked, components. For all 500 rooms, we didn’t use standard plastic gliders.

Instead, we supplied our ball-bearing wheeled runners. The difference in performance is night and day. These runners are designed for constant use. Each wheel distributes the curtain’s weight, allowing even a heavy, floor-to-ceiling blackout drape to be drawn with a gentle pull.

From a manufacturing perspective, this means ensuring the interior channel of the aluminum track is extruded to precise tolerances, with a perfectly smooth finish. It’s this synergy between a well-made track and a high-performance runner that creates the silent, smooth glide that guests associate with a quality hotel.

| Component | Standard System (Potential for Failure) | High-Use Hotel System (Our Solution) |

|---|---|---|

| Track | Lightweight aluminum or plastic | Commercial-grade, smooth-channel aluminum |

| Runners | Simple plastic friction slides | Ball-bearing wheeled runners |

| Operation | Can become stiff, noisy, or jam | Consistently smooth, silent, and effortless |

| Maintenance | Frequent calls to fix stuck curtains | Minimal maintenance required |

What track system is best for modern ripplefold blackout curtains?

Your design brief calls for a contemporary, clean look with ripplefold (or S-fold) curtains. You need a track system that is specifically compatible with this style to create perfect, uniform waves.

The best system for ripplefold curtains is a dedicated track with specially designed runners connected by a cord at fixed intervals. This cord spacing dictates the uniform "S" shape of the curtain, ensuring consistent folds from end to end.

The hotel’s design aesthetic was modern and minimalist, so ripplefold curtains were the obvious choice. This style eliminates traditional pleats and creates a sleek, architectural look. However, you can’t create a perfect ripplefold look with a standard track. For this project, we supplied a complete ripplefold system.

This included the aluminum track and, crucially, snap-tape runners. These runners are strung together on a cord at precise distances (e.g., 60mm, 80mm). The custom-made curtain has a simple flat tape sewn to the top, which then snaps onto these runners. This system forces the fabric into the signature S-curve. We had to calculate the exact number of runners needed for thousands of different window widths across the hotel, ensuring that every single curtain, whether in a standard room or a presidential suite, had the same flawless, consistent wave pattern.

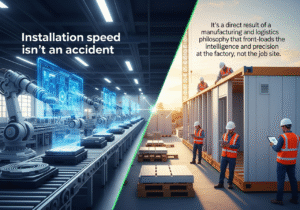

How do you manage logistics for a 500-room installation?

The product is specified, but now you face the enormous challenge of getting the right product to the right place at the right time, without causing chaos on the construction site.

Logistics for a large project are managed through phased deliveries and clear labeling. The supplier must pack and label each track set by room number or floor, and deliver them in scheduled batches that align with the installer’s workflow.

This was David’s biggest worry, and it’s where a good supplier proves their worth. A 500-room hotel isn’t built all at once; it’s completed floor by floor. Dumping thousands of curtain tracks on-site at the beginning would be a nightmare. Our solution was a meticulous "pack-by-room" strategy. We coordinated directly with the site manager to get the installation schedule. We then assembled, cut, and packaged the complete double-track system for each room individually.

Every box was clearly labeled: Floor 1, Room 101, Window 1. We then scheduled truck deliveries on a weekly basis, only sending the tracks for the floors that were ready for installation that week.

This Just-In-Time (JIT) approach minimized on-site storage, prevented items from getting lost or damaged, and allowed the installation team to work efficiently, simply taking the correct box to the correct room. It transformed a logistical nightmare into a streamlined process.

Conclusion

Successfully outfitting a 500-room hotel isn’t about one product. It’s about a complete system: the right dual-track design, high-performance components, and a logistical plan that guarantees seamless, scalable execution.