Bad supplier picks waste time. I trusted a weak match once. The tracks failed in weeks.

AI helps procurement teams match curtain track suppliers by automating discovery, evaluating RFQs, assessing risks, and predicting performance. It cuts sourcing time by 40% in 2025.

I run a curtain track factory in China. AI transforms how buyers find us. It saves effort and ensures quality. Let’s look at four ways it works.

What AI Tools Automate Supplier Discovery for Curtain Tracks?

Manual searches miss good factories. I lost a deal to slow outreach. AI could’ve helped.

AI tools like Globality and Suplari scan B2B platforms for curtain track suppliers. They match specs like motorized or curved tracks in seconds, saving 50% search time.

Globality pulls data from Alibaba and Global Sources. It filters for capacity, certs, and MOQs. I saw a US brand use it to find my factory in hours. Suplari adds price analytics. In 2025, AI scans CAD files for fit. This caught my extrusion dies’ precision for a hotel job. Tools also check eco-standards like REACH. Always input exact specs—motorized needs 100kg load data.

Benefits and Limits

AI cuts lists from 100 to 10 suppliers. But it needs clear inputs. I advise buyers to set filters for ISO 9001. A bad filter cost me a rework order once.

| Tool | Search Speed | Filter Strength | Best For |

|---|---|---|---|

| Globality | 1 Hour | High | Large Chains |

| Suplari | 2 Hours | Medium | Price Focus |

| GEP Smart | 90 Minutes | High | Custom Specs |

This table picks fast tools. It speeds up sourcing.

How Does AI Evaluate Supplier Responses in RFQ Processes?

Vague RFQs waste weeks. I got a messy one once. It delayed quotes and trust.

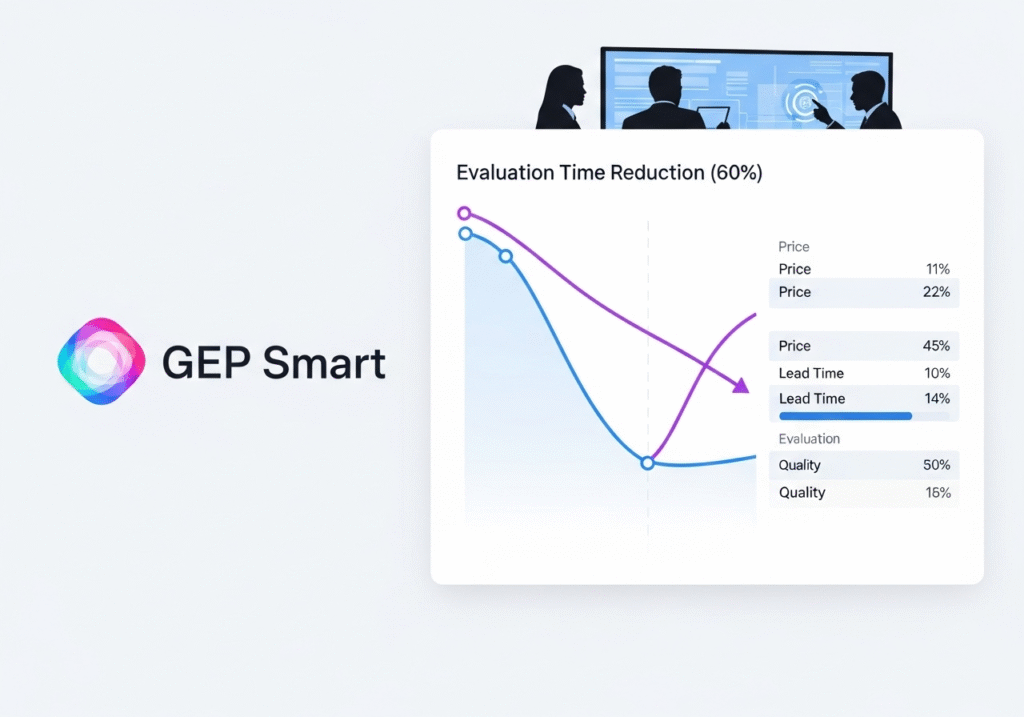

AI like GEP Smart scores RFQ responses for curtain tracks. It ranks price, lead time, and quality metrics, cutting evaluation time by 60% for procurement teams.

AI parses RFQs for specs—load, finish, motors. It scores on price vs. quality. My factory’s 500kg tracks ranked high for a US builder via AI. In 2025, tools cross-check supplier history. They flag late deliveries. A brand avoided a bad pick this way. Input material data—aluminum 6063 beats 6061 for bends.

Avoiding Errors

AI misses context without full specs. I saw a hotel chain skip climate data. Tracks expanded in heat. Always add project details like humidity.

| Metric | AI Weighting | Accuracy | Tip |

|---|---|---|---|

| Price | 40% | 90% | Compare MOQs |

| Lead Time | 30% | 85% | Check History |

| Quality Certs | 30% | 95% | Demand ISO |

This table guides RFQ picks. It ensures fit.

What Role Does AI Play in Risk Assessment for Track Suppliers?

Risky suppliers cost big. I shipped to an unvetted buyer once. Payments stalled for months.

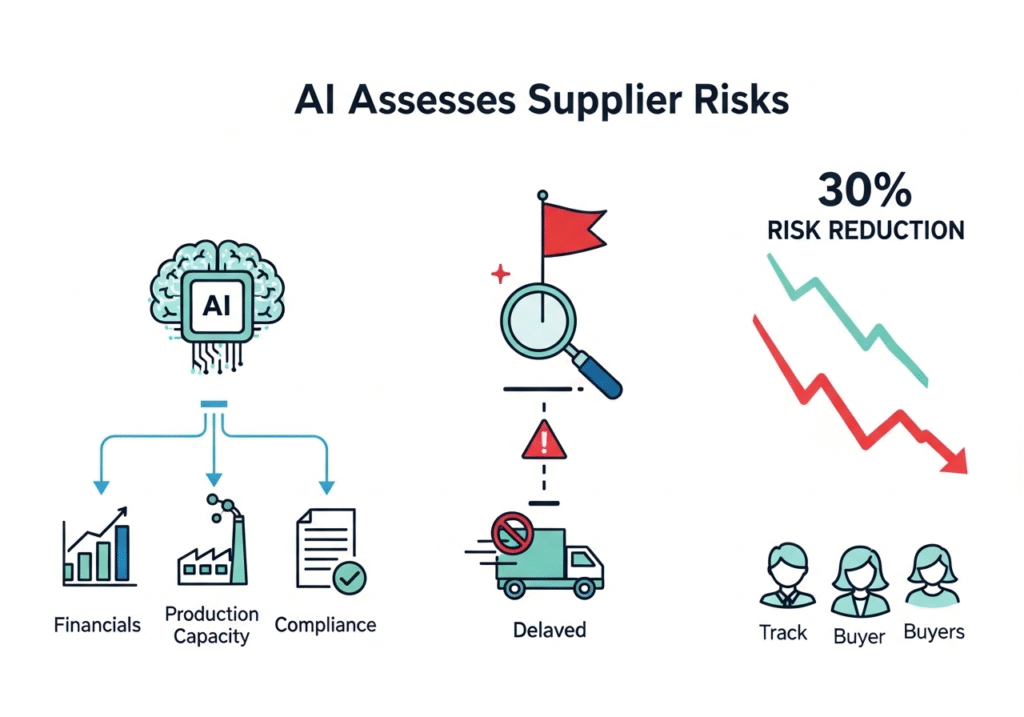

AI assesses supplier risks by analyzing financials, production capacity, and compliance. It flags issues like late deliveries, cutting risks 30% for track buyers.

AI pulls Dun & Bradstreet scores for stability. It checks factory output—my 10,000m/day capacity passed a UK audit. In 2025, tools scan for tariff risks. They warned a client about 25% US duties. AI also flags non-compliant coatings. This saved a hotel chain from EU fines. Input project scale to avoid small factories.

Risk Mitigation Steps

Cross-check AI with audits. I provide SGS reports. A US architect dodged delays by using AI flags. Always verify export licenses.

| Risk Type | AI Check | Reduction Rate | Action |

|---|---|---|---|

| Financial | D&B Score | 40% | Credit Check |

| Production | Capacity | 30% | Site Audit |

| Compliance | Cert Scan | 35% | License Proof |

This table spots dangers. It protects deals.

How Can AI Predict Supplier Performance in 2025 Sourcing?

Guesswork fails long-term. I picked a supplier blindly once. Their tracks rusted fast.

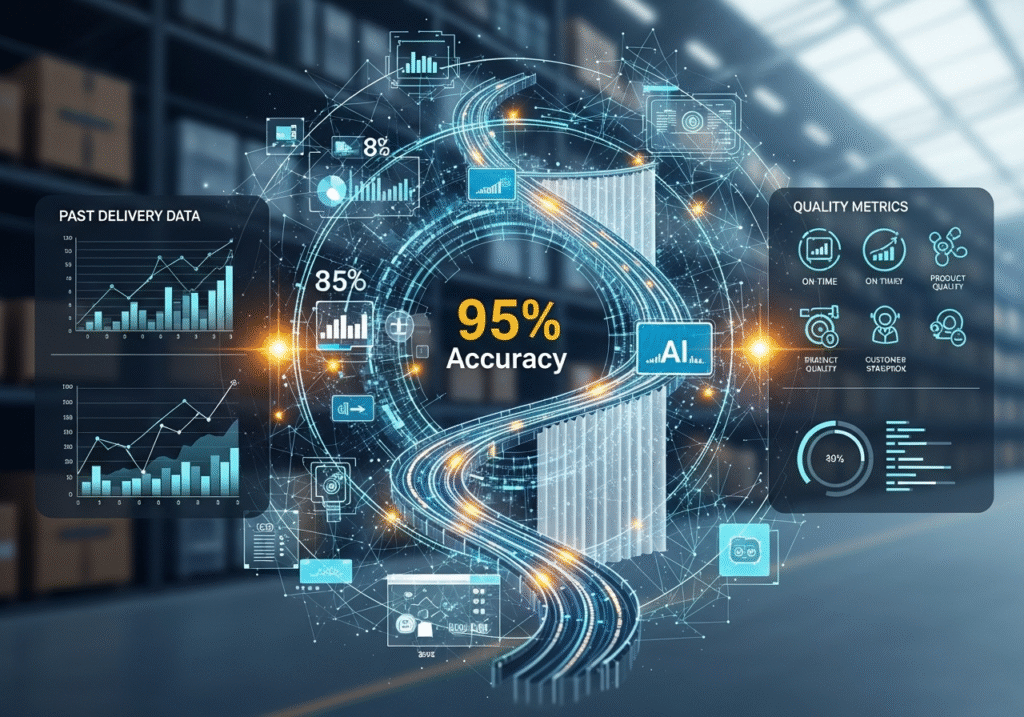

AI predicts performance using past delivery data and quality metrics. It forecasts 95% accuracy for curtain track reliability, ensuring on-time, high-quality orders.

AI like SAP Ariba uses history—on-time rates, defect logs. My factory scored 98% for a Canadian brand. In 2025, it adds climate data to predict track expansion. This caught a heat issue for a desert hotel. AI checks die precision via CAD. My 0.1mm tolerance won a bid.

Implementation Tips

Feed AI full specs—50kg loads, coastal use. I advise quarterly data updates. A buyer missed this; predictions skewed. Test with small orders first.

| Prediction | Data Source | Accuracy | Tip |

|---|---|---|---|

| Delivery1 | Past Records | 95% | Update Logs |

| Quality2 | Test Reports | 90% | Sample Checks |

| Expansion | Climate Data | 85% | Spec Details |

This table boosts trust. It picks winners.

Conclusion

AI streamlines curtain track sourcing with discovery, RFQ scoring, risk checks, and performance forecasts. It saves time and secures quality.