You’ve received three quotes for curtain tracks, and they all look similar. But choosing the wrong supplier based on price alone can lead to disastrous project delays and product failures.

You must ask about the specific grade of aluminum, their capabilities for customization (bending and cutting), what components are included as standard, and their production capacity and typical lead times for large orders.

This is a conversation I have almost every day. An experienced purchasing manager like Matt doesn’t just send a drawing and ask for a price. He digs deeper. I remember the first time we worked together on a large order. He had a full page of questions ready. He wasn’t just buying a product; he was vetting a partner who could guarantee quality and reliability for a multi-million dollar project. He knew that the real cost of a supplier isn’t on the invoice—it’s in the potential for error, delays, and poor quality. The questions you ask upfront are the best insurance for your project’s success.

What are the material specifications and finish options?

You see "aluminum track" on a quote, but this simple term can hide a huge range in quality. You need to know exactly what you’re paying for to avoid weak, easily-damaged products.

Always ask for the specific aluminum alloy (e.g., 6063-T5 is a common standard for architectural profiles) and the thickness of the profile wall. Also, confirm the powder coating or anodizing specifications to ensure a durable, long-lasting finish.

This is the most fundamental question, and a good supplier will have a clear answer. On the factory floor, I see the difference. A cheaper alloy might be more brittle, and a thinner profile wall will bend under the weight of heavy commercial curtains. I always advise buyers to request a technical data sheet. It should clearly state the material grade. Beyond the raw material, the finish is vital. For our tracks, we use a high-grade powder coating process that resists scratching and chipping, which is essential in a high-traffic hotel environment. A cheap paint finish might look fine out of the box, but it won’t stand up to daily use and cleaning. Asking this question separates the professional manufacturers from the simple traders.

| Specification | What to Ask For | Why It Matters |

|---|---|---|

| Material | Specific alloy grade (e.g., 6063-T5) | Ensures strength, rigidity, and durability |

| Profile | Wall thickness in millimeters (mm) | Prevents bending and sagging under load |

| Finish | Powder coating or anodizing thickness | Guarantees scratch resistance and longevity |

Can you supply custom-bent or cut-to-size tracks?

Your project includes bay windows, curved walls, or non-standard window lengths. You need a supplier who can provide precise, ready-to-install solutions, not just standard 6-meter lengths.

A capable manufacturer must confirm their ability to factory-bend tracks to your specified radius and cut tracks to precise lengths. This saves immense time and ensures a perfect fit, eliminating costly on-site modifications and errors.

On-site fabrication is a recipe for inconsistency and added labor costs. For any project with unique architectural features, factory customization is key. When a client sends us blueprints for a hotel with dozens of bay windows, we use CNC bending machines to ensure every single curve is identical and matches the specification perfectly. The same goes for length. For a 500-room project, cutting thousands of tracks on-site is inefficient and creates waste. We do all the cutting in our facility to a +/- 1mm tolerance.

The tracks arrive on-site labeled by room number, ready for immediate installation. Asking about a supplier’s customization capabilities tells you if they are a true manufacturing partner or just a distributor.

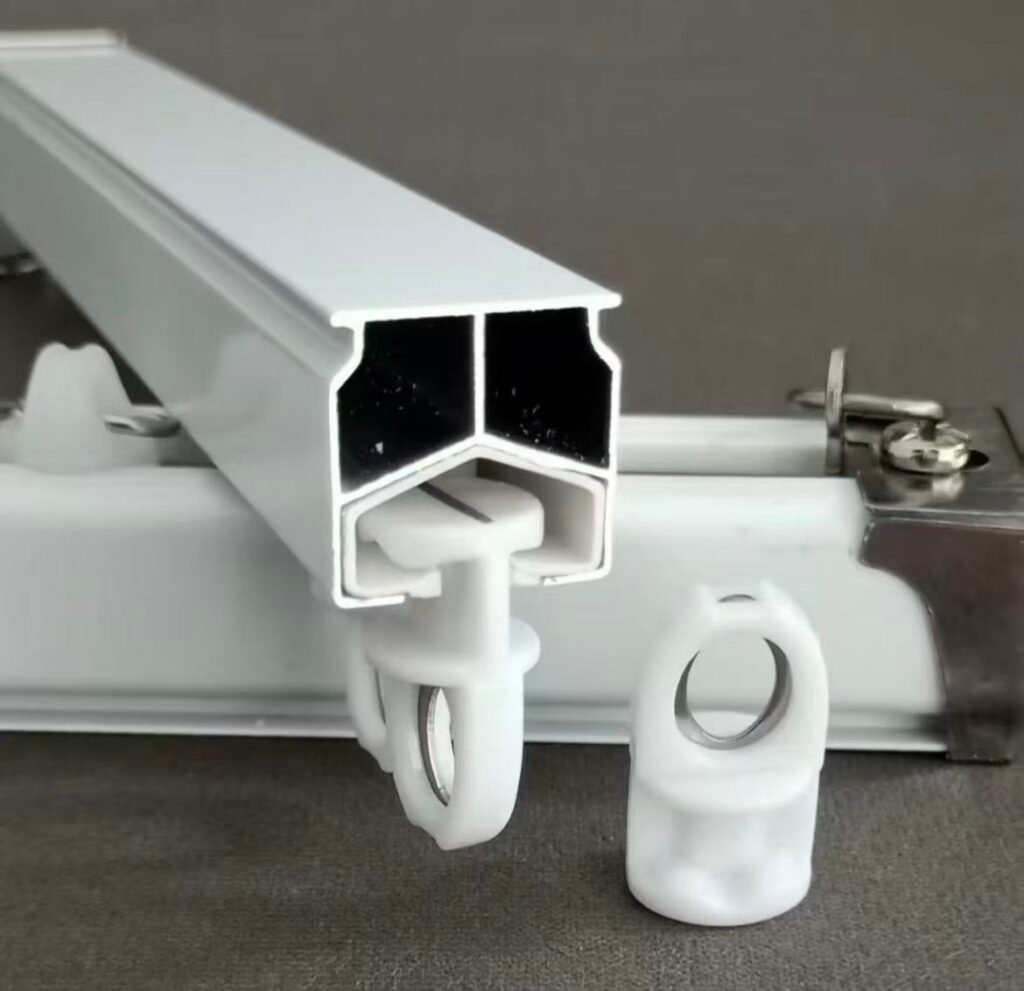

What components are included with the track?

You’ve received a price per meter for the track, but you need to know if that includes all the necessary parts. Hidden costs for essential components can quickly inflate your budget.

Ask for a clear list of what is included as standard. This should specify the number of runners/gliders per meter, the type and number of brackets, and if end caps are included. A complete solution is always better value.

A low price for a "track" can be misleading if you then have to place separate orders for every other part. This complicates purchasing and can lead to compatibility issues. Our standard practice is to quote a complete system. We’ll specify, for example: "Price includes aluminum track, 12 wheeled runners per meter, 1 heavy-duty ceiling bracket every 50cm, and two plastic end caps per piece." This transparency is crucial for accurate budgeting. You should never have to guess what’s in the box.

A professional supplier will work with you to ensure you have the right number of high-quality components for your specific curtain weight and mounting needs, providing everything in one simple, clearly-defined package.

What is your production capacity and typical project lead time?

You have a strict construction schedule. A supplier who cannot produce and deliver on time can bring your entire project to a standstill, costing you thousands in penalties and delays.

Ask for their production capacity (e.g., meters of track per week) and a realistic lead time for an order of your size. For large projects, also ask if they can support a phased delivery schedule.

This question separates the large, reliable factories from smaller workshops. When a client like Matt needs tracks for a 500-room hotel, he needs to know we have the machinery and manpower to handle the volume without our quality dropping or other orders causing delays.

I can tell him, for example, that our extrusion lines can produce 20,000 meters a week and that a typical 5,000-meter order takes 4 weeks from confirmation to shipping. More importantly, we can commit to a phased delivery plan, shipping tracks for 5 floors at a time to match the installers’ progress. A supplier who is vague about their capacity or lead times is a major red flag. You need a partner who can confidently commit to your schedule and has a proven track record of delivering large projects on time.

Conclusion

Asking these targeted questions about material, customization, components, and capacity will transform your sourcing process. It allows you to find a true partner who provides value and reliability, not just a low price.