How Can I Verify the Quality of Curtain Tracks Before Importing?

Importing a container of low-quality curtain tracks is a nightmare. It leads to customer complaints, wasted money, and a damaged reputation. Verifying quality before you import is your best protection.

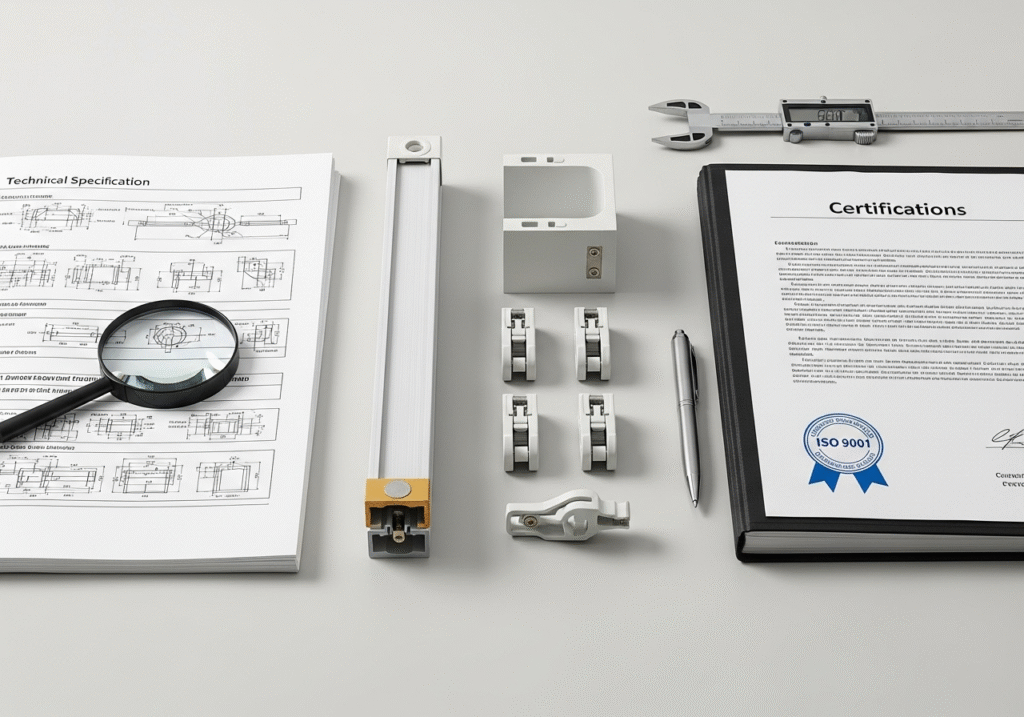

To verify quality, request detailed technical specifications and order physical samples. Critically inspect the track's material thickness, finish, and components like gliders and brackets. Finally, ask for relevant manufacturing certifications like ISO 9001 to ensure consistent production standards.

I know the pressure a purchasing manager like Matt is under. A single bad shipment from overseas can destroy a quarter's profitability. He needs a reliable way to spot problems before that container ever leaves the port. Having started on the factory floor, I’ve been on both sides of this equation—making the products and ensuring they meet global standards. It all comes down to knowing exactly what to look for, long before the products are on the water.

How can I verify quality and measure for curtain tracks before importing?

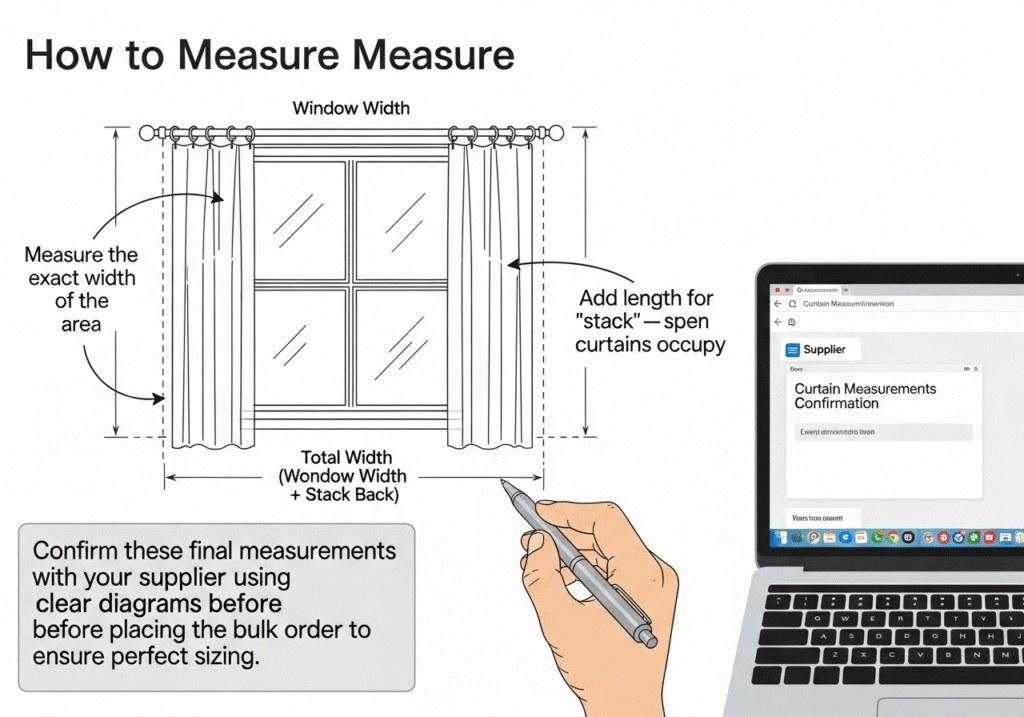

Wrong measurements are a simple but costly mistake. An entire shipment of tracks could be the wrong size, causing massive project delays and financial losses. A clear process prevents these errors.

Measure the exact width of the area, then add length for "stack back"—the space the open curtains occupy. Confirm these final measurements with your supplier using clear diagrams before placing the bulk order to ensure perfect sizing.

Combining correct measurement with quality verification is key. You can't have one without the other. An perfectly measured but poor-quality track will still fail. I always advise partners to integrate their measurement process with their quality checks.

The Golden Rule of Measurement

The process is straightforward, but it demands precision. First, measure the exact width of the window or space you need to cover. This is your "coverage width." Next, decide how much space the curtains will take up when they are fully open. This is called the "stack back," and it's typically 15-30% of the coverage width. Your final track length should be the coverage width plus the stack back. Always double-check these numbers and provide the supplier with a simple drawing. This leaves no room for interpretation errors.

Connecting Measurement to Quality

Once you provide your measurements, especially for long spans, use it as a quality test. Ask your supplier how their track's profile and thickness prevent sagging over that specific length. A quality manufacturer can provide load-bearing data1. Furthermore, for tracks longer than the standard stock length, ask to see their connectors. A quality supplier will have engineered connectors2 that create a seamless, strong joint, ensuring gliders pass over it without a single bump. A poor quality connector will be a point of failure.

How can I verify and check the quality of curtain tracks before importing?

A product looks perfect in professional photos but feels flimsy and cheap in your hand. Relying on pictures alone is a gamble that often leads to disappointment and costly returns.

You must get a physical sample. Check the aluminum wall thickness, inspect the powder coating for defects, and test the gliders for a smooth, silent run. The tactile experience will reveal quality issues that photos can hide.

The single most important step in verifying quality is to get your hands on the product. Pictures can be deceiving, but a physical sample tells the truth. When I send a sample to a discerning partner like Matt, I know he is going to put it through a series of hands-on tests. This is what you should do, too. Create a simple inspection checklist to evaluate every sample you receive.

Your Hands-On Inspection Checklist

Use this structured approach to test your sample:

| Inspection Point | What to Look For | Quality Signs | Red Flags |

|---|---|---|---|

| Track Finish | Check the powder coating or paint. | Smooth, even color, no blemishes. | Scratches, bubbles, uneven texture. |

| Track Structure | Measure wall thickness. Flex it gently. | Thickness of 1.2mm+ for heavy duty. Rigid. | Thin walls (<1.0mm). Bends easily. |

| Gliders/Carriers | Slide them back and forth in the track. | Silent, effortless glide. Snug fit. | Scraping noise, jamming, loose fit. |

| Components | Inspect end caps, brackets, connectors. | Sturdy plastic/metal. Clean molding. | Flimsy plastic, sharp edges, poor fit. |

This physical check takes less than five minutes but can save you thousands of dollars and protect your brand’s reputation. If a manufacturer is hesitant to send a sample, that is a major red flag in itself.

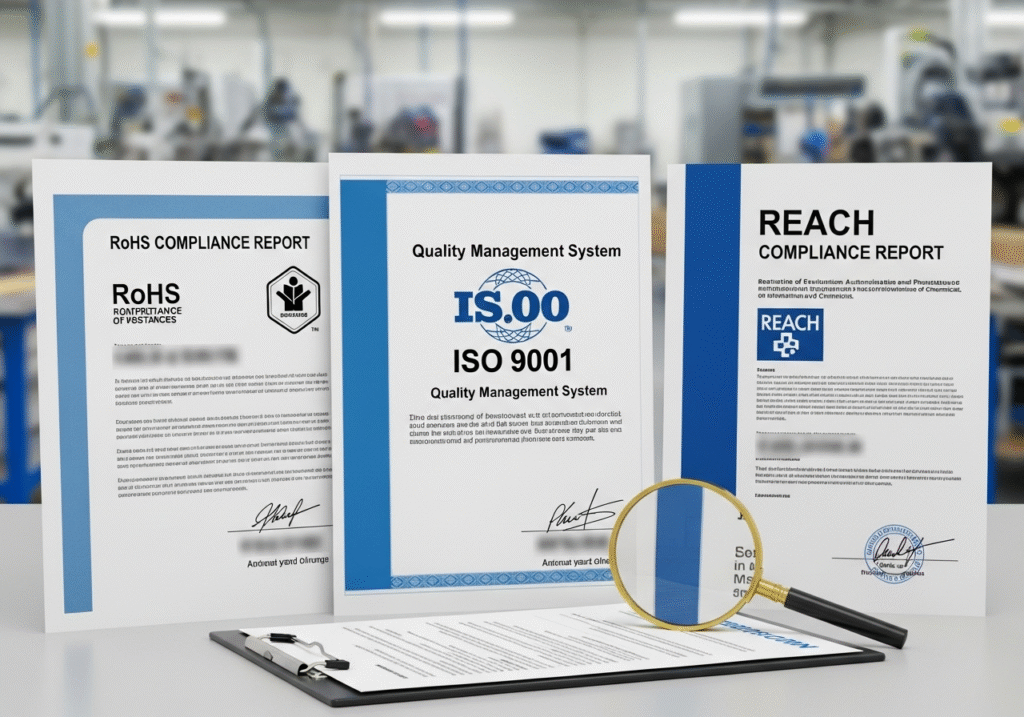

Which tests or certifications should I look for when importing curtain tracks?

Your shipment is stuck in customs or fails a commercial building inspection. Missing the right paperwork can cause huge delays and legal problems, putting your entire project and reputation at risk.

For manufacturing process, look for ISO 9001. For material quality and safety, request RoHS or REACH compliance reports, especially for plastics and finishes. These certifications prove a supplier's commitment to quality and regulatory standards.

Certifications are not just papers; they are proof of a manufacturer's commitment to quality and safety. They show that an independent third party has verified their processes and products. For an importer, this is a powerful way to reduce risk. While there are many certifications, a few key ones are essential for curtain tracks.

Decoding Key Certifications

Instead of getting lost in acronyms, focus on what they mean for your business.

- ISO 90011: Quality Management: This is the most important one. It doesn't certify the track itself, but it certifies the factory's processes. It proves the manufacturer has a documented, audited system for quality control3, from sourcing raw aluminum to inspecting the final product. A factory with ISO 90014 is far more likely to produce a consistent, reliable product shipment after shipment.

- RoHS and REACH: Material Safety: These are crucial for products sold in Europe and states like California. RoHS (Restriction of Hazardous Substances) restricts the use of specific hazardous materials like lead and mercury. REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is even broader. These certifications ensure the plastics, paints, and metals in your tracks are safe for end-users and the environment.

Always ask your potential supplier for copies of these certificates. A professional manufacturer will have them readily available.

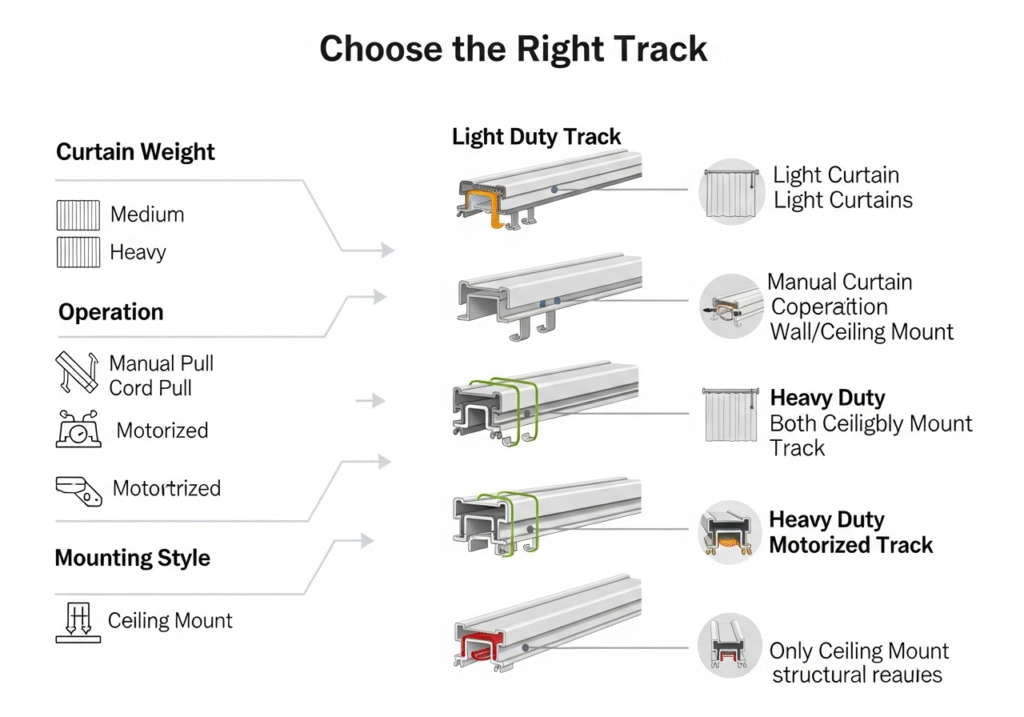

How can I verify quality and choose the right curtain track before importing?

Faced with dozens of track options, choosing the wrong one can mean poor performance. A track that's too weak for a heavy curtain or too bulky for a tight space is a wasted investment.

Choose the right track by matching its specifications to its intended use. Define the curtain's weight, the desired operation (manual or motorized), and the mounting style (wall or ceiling), then select a track that meets those needs.

Choosing the "right" track is the final step in quality verification. It’s about ensuring the product is not only well-made but also perfectly suited for the job. From my manufacturing perspective, this means aligning the engineering of the track with the customer's real-world application. I guide my partners to think through three critical questions.

1. What is the Weight and Function?

First, determine the curtain's weight. A sheer, lightweight panel needs a very different track than a heavy, lined velvet curtain. Ask the supplier for the track's load capacity, usually specified in pounds or kilograms per foot. Next, consider the function. Is it for a hotel room that will be used daily, or a conference room that's used weekly? High-use environments demand more durable gliders and stronger track profiles.

2. How Will It Be Operated?

Will the curtain be opened by hand, with a wand, or by a motor? For manual operation, especially with heavy curtains, the smoothness of the gliders is paramount. For motorized systems, you need to verify that the track is compatible with the motor's belt and drive system. A quality manufacturer will offer complete, tested systems, not just individual parts.

3. What is the Mounting Style?

Where will the track be installed? A track designed for ceiling mounting may not have the right brackets for a wall installation. For recessed or ceiling-mounted tracks, ensure the profile is designed for that specific look. Confirm that the supplier provides all the necessary hardware—brackets, screws, and end caps—for your chosen installation method.

Conclusion

Verify track quality by checking samples, demanding certifications, and matching the product to the job. This protects your investment, ensures performance, and builds a reputation for delivering reliable, high-quality solutions.

Related:

-

Understanding load-bearing data is crucial for ensuring the structural integrity of your tracks, making this resource invaluable. ↩ ↩

-

Exploring engineered connectors can help you learn about their advantages in creating strong, seamless joints for your tracks. ↩

-

Exploring quality control practices can help improve product consistency and reliability. ↩

-

Understanding ISO 9001 is crucial for ensuring quality management in manufacturing processes. ↩